How to Choose Advanced Manufacturing Machines for Your Business Needs?

In today's rapidly evolving industrial landscape, selecting the right advanced manufacturing machines is crucial for businesses seeking to optimize productivity and efficiency. According to a recent report by the International Federation of Robotics, the global market for advanced manufacturing machines is expected to grow by 22% annually over the next five years. This growth highlights the growing reliance on sophisticated technologies in manufacturing.

Dr. Amanda Chen, a leading expert in advanced manufacturing technologies, emphasizes, "Investing in modern machines can significantly impact a company's bottom line." However, choosing the right machines involves careful consideration. Critical factors include production needs, budget, and technology compatibility. Businesses must ask themselves: Do these machines align with our long-term goals?

Moreover, mistakes in selecting advanced manufacturing machines can lead to operational inefficiencies. Each wrong choice can cost both time and resources. Companies should engage in thorough research and possibly seek expert advice to navigate this complex decision-making process. Identifying the ideal machines takes effort but is essential for staying competitive.

Understanding Your Business Requirements for Advanced Manufacturing

Understanding your business requirements is critical when selecting advanced manufacturing machines. Begin by assessing your production volume. Will you need a few pieces of equipment for small-batch production? Or are you aiming for high-volume output? Knowing your needs helps narrow down options significantly.

Next, consider the types of materials you will use. Different machines handle various materials differently. It is crucial to match machine capabilities with material specifications. Don't overlook compatibility. Some machines might not produce the quality you expect with certain materials.

Lastly, think about the long-term goals of your business. Are you planning to expand? This could influence your purchasing decision. Investing in machines that allow for scalability might save costs down the line. However, be cautious; sometimes, they come with complexities that can overwhelm staff. Reflecting on these factors can help refine your choices and lead you toward effective solutions.

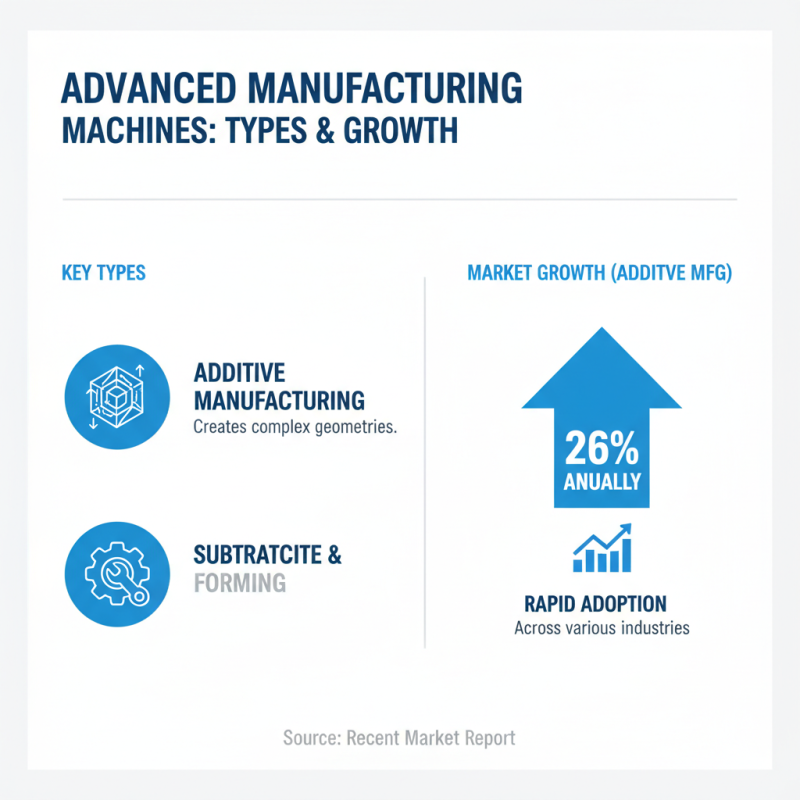

Evaluating Different Types of Advanced Manufacturing Machines

When evaluating advanced manufacturing machines, understanding their types is crucial. Each type serves specific needs. For instance, additive manufacturing machines offer unique capabilities in creating complex geometries. According to a recent market report, the additive manufacturing market is expected to grow by 26% annually. This rapid growth indicates increasing adoption across various industries.

Another key type involves subtractive manufacturing machines, like CNC machines. They are essential for precision tasks. A study shows that companies using CNC technology report a 30% increase in production efficiency. However, this efficiency might come at a higher initial cost. Businesses need to analyze their long-term return on investment carefully.

Robotic automation has also become vital. It helps enhance production speed and consistency. The International Federation of Robotics reported a 16% rise in robotic installations in manufacturing sectors last year. Yet, companies must consider the costs associated with training employees to work alongside robots. Advanced machines can optimize production, but integrating them may pose challenges. It's necessary to reflect on these factors to make informed choices.

Key Features to Consider in Manufacturing Machinery Selection

When selecting advanced manufacturing machines, several key features should be carefully evaluated. Production speed is essential. Reports suggest that machines with higher operational speeds can lead to a 30% increase in productivity. It’s vital to balance speed with precision. Machines that only focus on speed might compromise accuracy, leading to quality issues.

Another crucial factor is adaptability. As market demands shift, your machinery should adjust accordingly. A flexible machine can handle various materials and products. This adaptability reduces downtime and increases efficiency. According to recent industry research, adaptable machinery can improve overall operational efficiency by 20%.

Tips:

- Evaluate your current and future production needs.

- Consider the total cost of ownership; this includes maintenance and training.

- Look for machines that offer easy integration with existing systems.

A machine's energy consumption is also worth noting. Energy-efficient models save costs in the long run. However, the initial investment can be higher. Sometimes, businesses underestimate the operational expenses associated with equipment. Investing in energy-efficient machines can yield returns, but the timeline may vary. Review the long-term savings against upfront costs carefully.

Analyzing Cost vs. Benefit for Machine Investment Decisions

Investing in advanced manufacturing machines can be challenging. Businesses often weigh costs against potential benefits. It's vital to analyze operational needs carefully. This process must factor in both upfront costs and long-term savings. For example, a machine that automates labor-intensive tasks might seem expensive initially. However, it can reduce labor costs over time and increase productivity.

On the other hand, the wrong choice can be detrimental. A more affordable machine may lack the necessary features, leading to inefficiencies. Sometimes, companies overlook how these decisions impact quality. Lower initial investment doesn’t always mean smarter spending. Evaluating the total cost of ownership is crucial. This includes maintenance and potential downtime.

Next, consider future growth. Machines that can adapt or scale can offer better returns. Sometimes, businesses fixate on immediate savings, ignoring future needs. An emotional attachment to a specific technology can cloud judgment. Reflect on whether these investments align with long-term business goals. Each machine demands a thoughtful approach to ensure it drives value.

Researching and Comparing Manufacturers and Suppliers

When considering advanced manufacturing machines, researching manufacturers and suppliers is vital. Begin with a clear understanding of your specific needs. Look for factors like machine capability, technology, and service options. A broad internet search can lead you to various companies, but take time to dive deeper into their offerings.

Tips: Always check for customer reviews. Positive feedback is a good sign. However, don't ignore negative comments. They often reveal important details. Compare at least three suppliers to see differences. This helps you gain a better perspective.

Visit trade shows or exhibitions if possible. They allow you to inspect machines firsthand. You can see how they operate in real time. However, times may feel rushed, and some machines may not perform as advertised. Take notes during these visits; revisit them later when you assess each supplier’s reliability.

Always ask manufacturers about their after-sales support. A great machine is only as good as the service behind it. Be cautious of promises that seem too good to be true. Each choice made will impact your business’s effectiveness. Reflect on each information source. This method will guide you towards making informed decisions.

Advanced Manufacturing Machines Comparison

Related Posts

-

Top 10 Manufacturing Machines Transforming the Industry in 2023

-

Why Simple Manufacturing Machines Are Essential for Modern Production

-

Top 10 Tips for Optimizing Manufacturing Machines for Maximum Efficiency

-

How to Choose the Right Manufacturing Equipment for Your Business Needs

-

Top 10 Manufacturing Machinery and Equipment for Increased Efficiency

-

Why You Should Invest in a Diaper Machine for Your Business Today