How to Choose the Best Small Industry Machine for Your Business Needs

In today's rapidly evolving market, selecting the right small industry machine can significantly impact the productivity and efficiency of your business. As industry expert John Smith, a seasoned engineer with over 20 years of experience in the manufacturing sector, aptly puts it, "A well-chosen small industry machine is not just a tool; it’s a catalyst for growth." This statement underscores the importance of making informed decisions when investing in machinery tailored to smaller industrial operations.

Choosing the best small industry machine involves understanding your specific business needs, operational demands, and the unique features that different machines offer. Whether you are a startup looking to optimize production or an established business aiming to upgrade equipment, the right small industry machine can streamline operations and enhance performance. Therefore, it is crucial to evaluate factors such as the machine's functionality, versatility, and ease of maintenance to make a wise choice that aligns with your long-term goals.

As we delve deeper into the complexities of selecting the ideal small industry machine, we will explore essential considerations and expert insights that can guide you through this pivotal decision-making process. The impact of the right machinery on business success is profound, and understanding what to look for will enable you to make choices that elevate your operations to new heights.

Understanding Your Business Requirements for Small Industry Machines

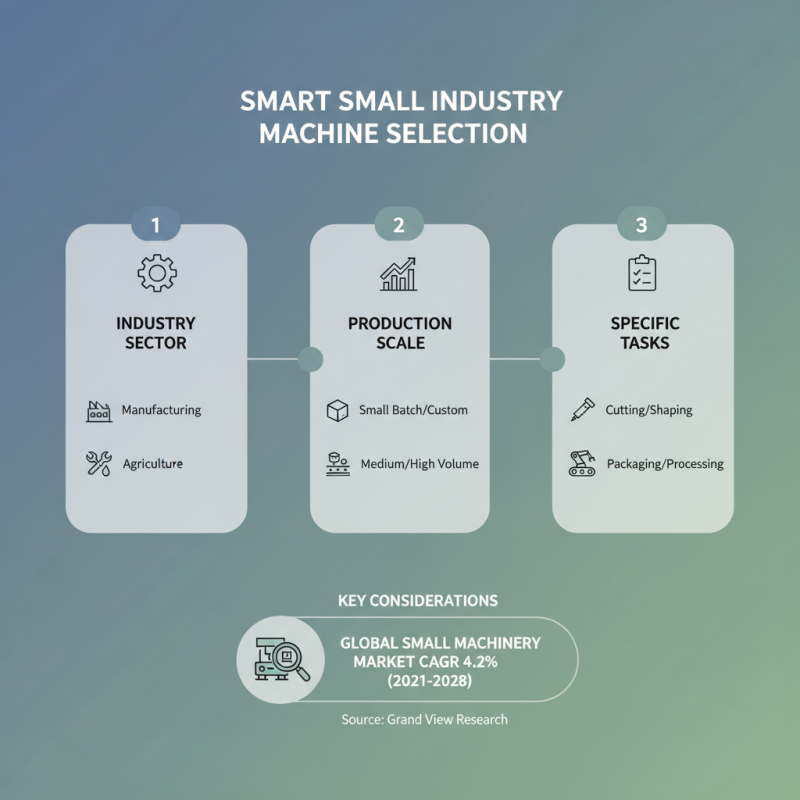

When selecting the best small industry machine for your business, understanding your specific requirements is crucial. The type of machine needed often depends on the industry sector, production scale, and the specific tasks it needs to accomplish. According to a market research report by Grand View Research, the global small machinery market is expected to grow at a CAGR of around 4.2% from 2021 to 2028, indicating a rising demand for efficient and versatile machines in various industries.

Tips: Begin by assessing the scale of your operations. If your business revolves around low to medium production volumes, investing in multifunctional machines can enhance efficiency and reduce costs. Additionally, take into account the machine's operational requirements, including power consumption and space availability, as these factors can significantly impact your overall productivity.

Another vital aspect is the level of technical support and maintenance required by the machine. A survey conducted by the Machinery Dealers National Association revealed that businesses often underestimate maintenance costs, which can lead to unplanned downtime and increased expenses. Before making a purchase, evaluate potential suppliers for their reliability and the support services they offer, ensuring you can maintain a smooth and efficient operation.

Assessing the Space and Installation Needs for Equipment Choices

When selecting the best small industry machine for your business, it's crucial to assess both

space and

installation requirements to ensure

optimal operational efficiency. According to a recent industry report by

Market Research Future, over 60% of small business

owners have reported that machine footprint and installation constraints significantly impact

their equipment choices. Therefore, evaluating your available workspace is the first step

in this decision-making process. This involves measuring not only the area where the machinery

will occupy but also considering the layout for operational flow and safety compliance.

Installation needs are equally important. Many small industry machines require specific

utilities such as power supply, compressed air, or ventilation systems. A survey conducted

by the Association for Manufacturing Technology

revealed that nearly

45% of businesses experienced installation

delays due to inadequate facility preparation. To mitigate such issues, engaging with equipment

suppliers during the planning phase can enhance understanding of installation prerequisites.

Furthermore, ensuring that your facility can accommodate required revisions, like reinforced

flooring or upgraded electrical circuits, will minimize disruptions and maintain productivity

during installation. Assessing these factors thoroughly will guide you to make informed and

strategic investments in

machinery that best suits your business needs.

Installation needs are equally important. Many small industry machines require specific

utilities such as power supply, compressed air, or ventilation systems. A survey conducted

by the Association for Manufacturing Technology

revealed that nearly

45% of businesses experienced installation

delays due to inadequate facility preparation. To mitigate such issues, engaging with equipment

suppliers during the planning phase can enhance understanding of installation prerequisites.

Furthermore, ensuring that your facility can accommodate required revisions, like reinforced

flooring or upgraded electrical circuits, will minimize disruptions and maintain productivity

during installation. Assessing these factors thoroughly will guide you to make informed and

strategic investments in

machinery that best suits your business needs.

Evaluating Machine Efficiency and Productivity Metrics in Industry

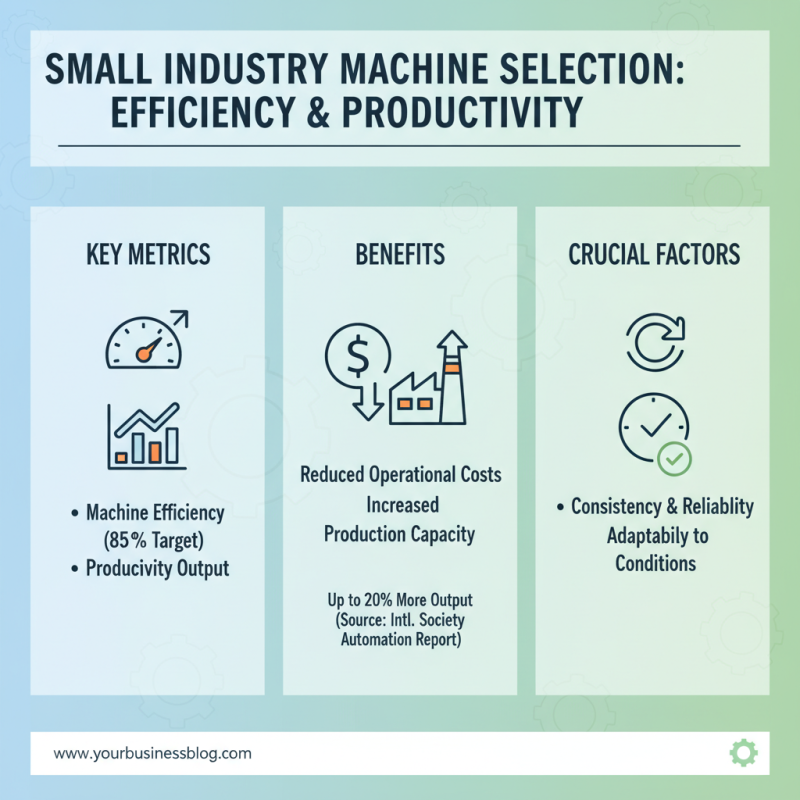

When selecting the best small industry machine for your business, evaluating machine efficiency and productivity metrics is crucial. A detailed analysis often reveals that high machine efficiency correlates with reduced operational costs and increased output. According to a report by the International Society of Automation, machines that operate at an efficiency rate of over 85% can produce up to 20% more output with the same amount of resources compared to less efficient models. This efficiency is not only about speed; it encompasses the consistency and reliability of performance across various operational conditions.

In addition to efficiency, measuring productivity metrics such as Overall Equipment Effectiveness (OEE) provides valuable insights into potential improvements. OEE combines machine availability, performance, and quality metrics into a single percentage. The Manufacturing Performance Benchmarking Study indicates that leading manufacturers achieve an OEE of over 75%, significantly higher than the average of around 60%. This data underscores the importance of choosing machines that not only meet your current needs but also have the potential to scale alongside your business. By investing in machines with proven efficiency and strong productivity metrics, businesses can enhance their competitiveness in a rapidly evolving industry landscape.

Comparing Cost, Maintenance, and Lifespan of Equipment Options

When selecting the best small industry machine for your business, comparing the cost, maintenance, and lifespan of equipment options is crucial. Equipment costs can vary significantly based on features and capabilities, making it essential to perform a cost-benefit analysis. Industry reports indicate that investing in higher-quality machines upfront can lead to a lower total cost of ownership over time. For instance, a durable machine might have a higher initial price but require less frequent repairs and replacement parts, thus safeguarding your long-term investment.

Regular maintenance is another key factor that plays a substantial role in the longevity and efficiency of your equipment. According to the Machinery Maintenance Association, a well-maintained machine can last up to 30% longer than one that is not properly cared for. Establishing a maintenance schedule that includes routine inspections and servicing can not only prevent unexpected breakdowns but also enhance operational productivity.

**Tips:** Consider investing in machines that come with robust warranties and customer support, as these can save you money in the long run. Additionally, look at user reviews and case studies to gauge how similar businesses have benefited from the equipment’s lifespan and maintenance needs. Prioritizing machines that offer easy access to parts and service will also streamline your operations and minimize downtime.

How to Choose the Best Small Industry Machine for Your Business Needs

| Machine Type | Cost (USD) | Maintenance Frequency (per year) | Average Lifespan (years) | Energy Consumption (kWh per month) |

|---|---|---|---|---|

| CNC Machine | $40,000 | 2 | 10 | 300 |

| Laser Cutter | $35,000 | 3 | 8 | 250 |

| 3D Printer | $15,000 | 1 | 5 | 150 |

| Vertical Milling Machine | $25,000 | 2 | 15 | 200 |

| Band Saw | $5,000 | 1 | 20 | 100 |

Researching Supplier Reputation and Customer Support Services

When selecting a small industry machine, one of the most critical factors to consider is the supplier's reputation. Researching how long a supplier has been in the business can offer insights into their stability and reliability. A well-established supplier is likely to have a proven track record and a portfolio of satisfied clients. Online reviews, testimonials, and case studies can also serve as valuable resources in assessing a supplier's performance. Reach out to existing customers if possible; their firsthand experiences can guide you in making an informed choice.

Customer support services from a supplier often determine the long-term success of your investment. Efficient and responsive support is crucial, especially during initial setup or in the event of technical issues. When evaluating suppliers, inquire about their support structure—whether they offer on-site assistance, training, or a helpline for troubleshooting. Understanding their response times and the comprehensiveness of their support resources can give you confidence in their ability to assist you post-purchase. Ultimately, a supplier that prioritizes customer service can enhance the longevity and productivity of your business operations.

Supplier Reputation and Customer Support Services for Small Industry Machines

This chart illustrates the importance of different factors when choosing a supplier for small industry machines, focusing on their reputation and customer support services.

Related Posts

-

2025 Top Trends in Manufacturing Industrial Machinery You Need to Know

-

Top 10 Manufacturing Machines Transforming the Industry in 2023

-

Why All Manufacturing Machines Are Essential for Modern Production Efficiency

-

Why Simple Manufacturing Machines Are Essential for Modern Production

-

Top 10 Diaper Manufacturing Equipment You Need for a Successful Factory

-

Top 10 Diaper Manufacturing Equipment You Need for Efficient Production