Top Equipment Manufacturing Trends Shaping the Future of Industry?

In today's rapidly evolving landscape, equipment manufacturing stands at a pivotal crossroads. The industry faces challenges and opportunities influenced by technological advancements and market demands. Many manufacturers are adopting automation and digital technologies. These innovations promise to enhance production efficiency. However, they also raise questions about job displacement and skills gaps.

Sustainability has become a focal point in equipment manufacturing. Companies are pressured to reduce waste and minimize environmental impact. Initiatives like circular manufacturing are gaining traction. Yet, there is a lingering debate about the cost and feasibility of these practices. Striking a balance between profit and responsibility is a pressing concern.

Moreover, the shift towards smart manufacturing emphasizes connectivity and data analytics. While this transformation can lead to improved performance, it necessitates robust cybersecurity measures. The journey towards the future of equipment manufacturing is fraught with complexities. Embracing change requires reflection and adaptability. The future remains uncertain, but one thing is clear: the path ahead will be shaped by innovation and thoughtful consideration.

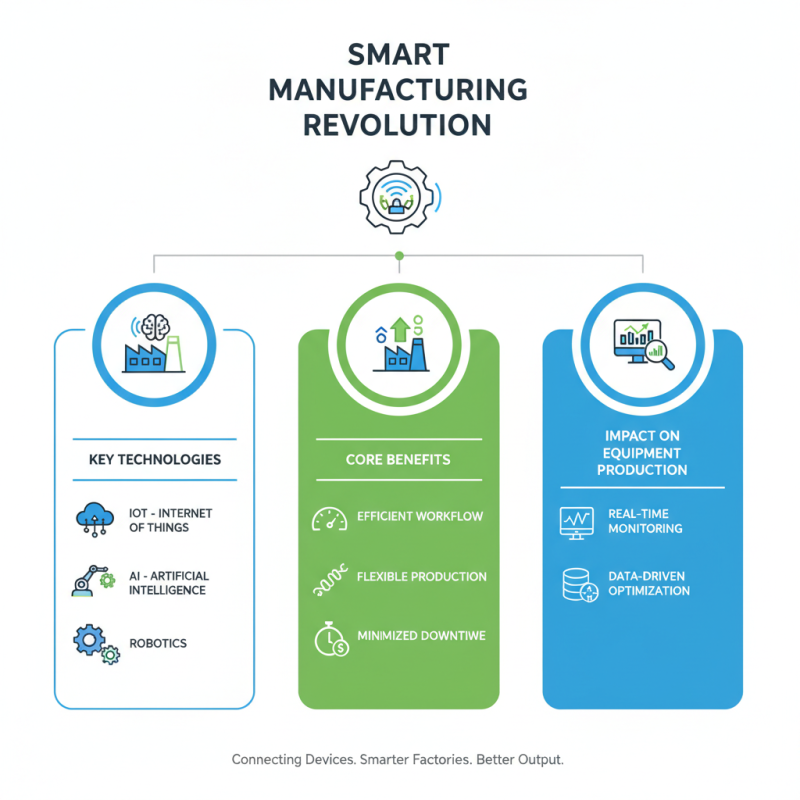

Emergence of Smart Manufacturing in Equipment Production

The rise of smart manufacturing is a game changer in equipment production. This trend is driven by technologies like IoT, AI, and robotics. These advancements create a more efficient and flexible workflow. Factories now use connected devices to monitor processes in real-time. Data is collected to enhance operational efficiency and minimize downtime.

However, the shift isn't without challenges. Not every facility can adapt quickly to these innovations. Workers need retraining to keep pace with new technologies. There’s also a concern about security. Cyber threats pose serious risks to connected systems. Maintaining data integrity is essential, but often overlooked in the rush to modernize.

Despite these hurdles, the potential of smart manufacturing is hard to ignore. Enhanced precision in equipment production leads to superior quality. Manufacturers can better meet customer demands with agile production lines. Yet, as the industry evolves, continuous reflection on practices is necessary. Embracing change is crucial, along with addressing weaknesses within systems. Only then can smart manufacturing fully realize its promise.

Integration of IoT and AI in Equipment Design and Maintenance

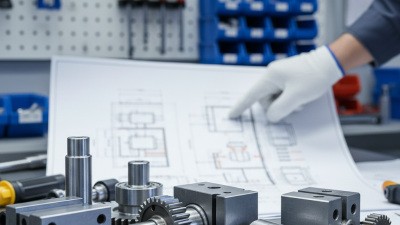

The integration of the Internet of Things (IoT) and artificial intelligence (AI) is transforming equipment design and maintenance. Smart sensors embedded in machinery collect real-time data, enabling predictive analytics. This data helps technicians anticipate potential failures before they occur, reducing downtime. Such proactive strategies are essential in industries where every minute counts.

However, the reliance on technology raises questions. What happens when systems fail? Can operators trust AI-generated insights fully? Human oversight remains critical. Balancing technology and human expertise is a challenge. Issues like data security and privacy concerns must also be addressed.

Despite these challenges, the benefits of IoT and AI are clear. They enhance efficiency and reduce costs. For instance, remote monitoring allows teams to diagnose issues from afar, saving travel time and resources. Yet, companies must be cautious about over-reliance. The future demands a hybrid approach, blending technology with human intuition and skills.

Integration of IoT and AI in Equipment Design and Maintenance Trends

Sustainability Practices in the Equipment Manufacturing Sector

Sustainability is becoming essential in the equipment manufacturing sector. Companies are adopting eco-friendly practices to reduce waste and energy use. More manufacturers now focus on renewable materials. This shift is not just ethical but also offers cost-saving benefits.

Tip: Evaluate your supply chain. Choose suppliers that prioritize sustainable practices. This helps create a more environmentally friendly production process.

Implementing recycling programs is another vital step. Some manufacturers struggle with waste management. Establishing clear protocols can improve efficiency. It is important not to overlook employee training in these initiatives.

Tip: Encourage feedback from workers. They often have valuable insights. Engaging your team can lead to innovative ideas for sustainability. Sustainable practices not only enhance brand reputation but can also drive innovation.

Top Equipment Manufacturing Trends Shaping the Future of Industry - Sustainability Practices in the Equipment Manufacturing Sector

| Trend | Description | Impact | Adoption Rate (%) |

|---|---|---|---|

| Circular Economy | Focus on reducing waste and encouraging recycling in production processes. | Minimizes resource depletion and enhances sustainability. | 45 |

| Green Technologies | Incorporating renewable energy sources and energy-efficient machinery. | Reduces carbon footprint and operational costs. | 52 |

| Digital Transformation | Utilizing IoT and AI to make equipment production smarter and more efficient. | Improves efficiency and reduces material wastage. | 60 |

| Sustainable Material Sourcing | Prioritizing biodegradable and recycled materials in manufacturing. | Promotes a positive brand image and compliance with regulations. | 30 |

| Life Cycle Assessment | Evaluating the environmental impact of products throughout their life cycle. | Informs better decision-making for sustainability initiatives. | 38 |

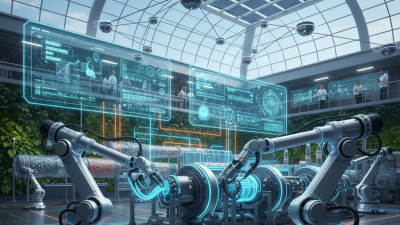

Advancements in Automation and Robotics for Enhanced Efficiency

Automation and robotics are reshaping the industry landscape. As companies strive for enhanced efficiency, they’re investing heavily in cutting-edge technologies. These advancements allow for faster production times. In many cases, machines work around the clock. This constant operation reduces downtime significantly.

The integration of robotics ensures precision. Tasks that once required human intervention are now automated. This shift raises questions about job displacement. While routine jobs may diminish, new roles emerge that focus on overseeing these technologies. Workers need to adapt quickly. Reskilling becomes essential in this evolving environment.

Furthermore, the reliance on automated systems highlights vulnerabilities. Cybersecurity threats grow alongside industrial automation. As organizations embrace smart machinery, they must also fortify their defenses. Balancing efficiency and security presents ongoing challenges. It’s vital for industries to address these concerns while reaping the benefits of automation.

Impact of Global Supply Chain Dynamics on Equipment Manufacturing Trends

The global supply chain dynamics significantly impact equipment manufacturing trends. Factors like sourcing and logistics are constantly evolving. These changes demand manufacturers to be agile and adaptive. The need for timely delivery is now more critical than ever. Companies must rethink their supply chain strategies to ensure resilience.

With geopolitical tensions and natural disasters affecting supply chains, the risks are high. This uncertainty forces manufacturers to be cautious and innovate. Many are exploring local sourcing options to reduce dependency on distant suppliers. However, this shift can increase costs and complicate the production process. Finding the right balance is essential.

Automation and digitalization also play a role in this transformation. Smart technologies enhance efficiency but require significant investment. Not every manufacturer can afford such upgrades. Some may find themselves lagging behind. The path forward is complex, where operational and financial decisions intertwine. Embracing change is vital, yet many questions remain unanswered.

Related Posts

-

2025 Top Trends in Manufacturing Industrial Machinery You Need to Know

-

How to Choose the Best Small Industry Machine for Your Business Needs

-

Top 10 Manufacturing Industrial Machinery Trends to Watch in 2023

-

Why Simple Manufacturing Machines Are Essential for Modern Production

-

How to Choose the Best Adult Diaper Machine for Your Needs

-

How to Choose the Right Manufacturing Machine Parts for Optimal Efficiency