What is Germany Machine and How Does It Impact Industry?

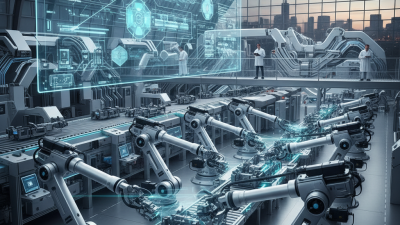

The concept of "germany machine" encompasses advanced technology used in various industries. Germany is renowned for its precision engineering and manufacturing prowess. Machines produced here play a crucial role in enhancing productivity and efficiency.

Industries benefit greatly from the innovations stemming from Germany. For instance, automotive and manufacturing sectors utilize these machines to streamline processes. However, the rapid integration of automation raises questions about job displacement and the need for workforce adaptation.

Despite these challenges, the impact of the germany machine is significant. It fosters competition and drives technological advancements. Yet, as industries embrace these changes, they must also consider the societal implications. Balancing progress with ethical considerations is essential for sustainable growth.

What is Germany Machine?

Germany Machine refers to the advanced industrial technology and equipment developed in Germany. This technology plays a key role in various sectors, such as manufacturing and automation. According to recent industry reports, Germany’s machine tools market is expected to reach $7 billion by 2025. This growth underscores the importance of innovative machinery in modern industry.

The efficiency of Germany machines is notable. They are designed for precision and reliability, which leads to higher productivity rates. For instance, a study found that automation increases production efficiency by up to 30%. However, challenges remain. Many companies face skills gaps as they adopt these advanced technologies. The need for skilled workers is critical, yet training programs often lag behind technological advancements.

Moreover, while Germany's machine technologies enhance output, they also require significant investment. Small to medium-sized enterprises may struggle with the financial burden. Observing the shift to automation, some experts argue that it could lead to job displacement. Balancing these advancements with workforce sustainability is a complex issue that the industry must address.

The Historical Development of Germany Machine

Germany's industrial landscape has been shaped significantly by its machine technology. The roots trace back to the late 19th century. Innovations emerged from the need for efficiency. Factories began to adopt mechanization, leading to mass production. This shift fueled Germany's economy and job market.

Over the years, continuous improvements transformed machinery design. Electric power became widespread, allowing for faster production cycles. However, this rapid advancement sometimes left workers behind. Skills became outdated quickly, leading to workforce challenges.

Tips: Embrace change but value learning. Reskilling can keep you relevant.

The post-war era saw a further technological leap. Precision engineering and automation gave Germany a competitive edge. Yet, not all advances have been perfect. The reliance on machinery also led to overproduction in some sectors. Balancing technology with sustainability remains a challenge.

Tips: Reflect on your industry's needs. Think about the long-term impact of automation.

Key Features and Technologies of Germany Machine

The Germany machine is a marvel of engineering. It combines precision with efficiency. Various key technologies drive its success in industry.

Robotics play a central role. These machines can perform tasks with minimal human intervention. This reduces the risk of errors. They increase productivity significantly.

Another important feature is data integration. Machines collect and analyze data in real-time. This allows for informed decision-making. Many companies overlook the importance of maintenance. A machine may perform well, but neglect can lead to failures. Operators should stay vigilant. Regular checks ensure that machines run smoothly.

In addition, flexibility is a crucial element. Germany machines adapt to various manufacturing needs. They can quickly switch between different tasks. However, this adaptability may come at a cost. Training personnel to operate these machines requires time and resources. Balancing these needs is essential for success in modern industry.

Impact of Germany Machine on Manufacturing Industry

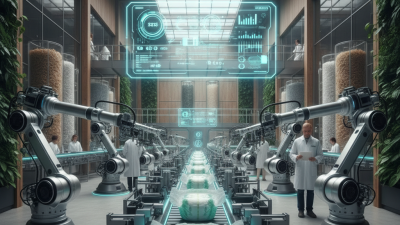

Germany's machine tools have significantly transformed the manufacturing industry. These machines introduce advanced automation and precision in production processes. Workers now rely heavily on technology, which has both positive and negative effects. Automated systems increase efficiency, but they also contribute to job displacement.

In manufacturing settings, Germany's machines enable higher production rates. The integration of robotics improves quality control. However, worker training remains a challenge. Employees must adapt to new technologies, which can be daunting. Some veteran workers feel left behind.

Companies need to invest in workforce development. Upskilling programs are essential for smooth transitions. The shift toward automation raises questions about the future of work. Will there be enough jobs for everyone? Balancing innovation and human labor is crucial for the industry’s success.

What is Germany Machine and How Does It Impact Industry? - Impact of Germany Machine on Manufacturing Industry

| Dimension | Description | Impact on Industry |

|---|---|---|

| Automation Level | Integration of robotics and automated systems in manufacturing processes. | Increases efficiency and reduces labor costs. |

| Precision Engineering | High-quality precision tools and machines that produce exact specifications. | Enhances product quality and reduces waste. |

| Energy Efficiency | Machines designed to use less energy while maintaining performance. | Lowers operational costs and supports sustainability goals. |

| Digitalization | Implementation of IoT and data analytics in machine operation. | Facilitates real-time monitoring and predictive maintenance. |

| Modular Design | Flexible machines that can be easily reconfigured for different tasks. | Allows for quick adaptation to market changes and diverse product lines. |

Future Trends and Innovations in Germany Machine

Germany is at the forefront of machine innovation. The country's manufacturing sector is evolving rapidly. Recent reports indicate that the German machine industry is expected to grow by 3% annually through 2025. This growth is largely driven by advancements in automation and data integration.

Emerging technologies are shaping the future landscape. Smart factories are becoming the norm. According to the latest industry analysis, about 60% of German manufacturers are adopting IoT solutions. However, the integration is not without challenges. Many companies struggle with data security and interoperability issues.

Sustainability is also a key focus. A significant number of manufacturers are investing in green technologies. Reports suggest that over 40% aim to reduce carbon emissions by 2030. Yet, this transition requires careful planning and commitment. Balancing innovation and sustainability poses a critical challenge for many.

Related Posts

-

Top 10 Germany Machine Innovations Transforming the Manufacturing Industry

-

Top 10 Diaper Manufacturing Equipment You Need for Efficient Production

-

Why All Manufacturing Machines Are Essential for Modern Production Efficiency

-

How to Choose the Best Small Industry Machine for Your Business Needs

-

Top 10 Benefits of Using a Pad Manufacturing Machine in Modern Production

-

What is Diaper Manufacturing Techniques and Their Importance in the Industry