Top 10 Germany Machine Innovations Transforming the Manufacturing Industry

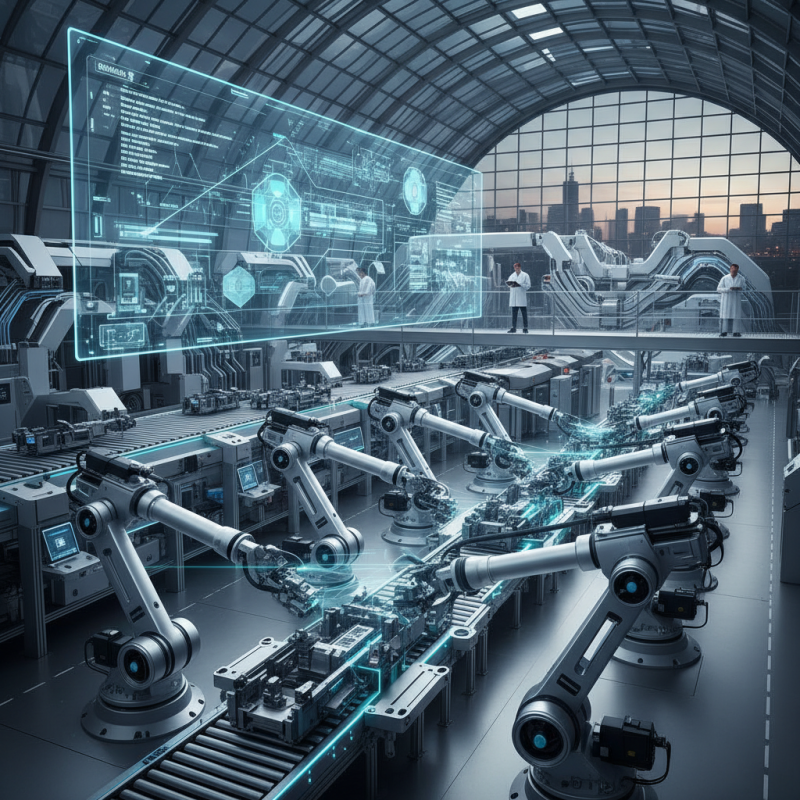

In recent years, the manufacturing landscape has witnessed a seismic shift, primarily driven by groundbreaking technological advancements. At the forefront of this transformation is the "Germany machine" sector, which has consistently showcased its prowess in innovation and efficiency. German manufacturers are renowned for their precision engineering and commitment to quality, making them leaders in the global manufacturing arena. The evolution of machinery in Germany not only enhances productivity but also addresses the challenges posed by Industry 4.0, where interconnected systems redefine operational capabilities.

The integration of advanced automation, artificial intelligence, and robotics within the Germany machine industry has reimagined traditional manufacturing processes. By leveraging these technologies, manufacturers can achieve unprecedented levels of efficiency, flexibility, and sustainability. As we delve into the top ten innovations propelling the German manufacturing industry forward, it becomes evident that these advancements are not merely improvements; they represent a fundamental shift in how machines and human labor can work in harmony to create superior products and drive economic growth. This evolution is not just beneficial for Germany; it sets a benchmark for industries worldwide, paving the way for a more technologically integrated future.

Advancements in Robotics: Revolutionizing Automation in German Factories

The German manufacturing industry is undergoing a significant transformation, with advancements in robotics leading the charge in revolutionizing automation. According to the International Federation of Robotics, Germany ranks among the top three countries globally in robot density, with over 338 industrial robots installed per 10,000 employees in the manufacturing sector. This high adoption rate positions Germany as a pioneer in the integration of robotics into production processes, allowing manufacturers to enhance efficiency, reduce costs, and maintain high-quality standards.

As automation technologies evolve, German factories are increasingly leveraging collaborative robots, commonly known as cobots, which work alongside human operators to streamline tasks. Research from McKinsey indicates that automation could increase productivity in manufacturing by up to 30% in the coming years while also addressing labor shortages in the sector. This shift not only boosts operational capabilities but also fosters an environment where human workers can focus on more complex and strategic roles, thereby redefining their contributions to the manufacturing process.

Moreover, the German government has allocated significant resources towards Industry 4.0 initiatives, anticipating that intelligent automation will add approximately €1 billion to the national economy by 2025. This investment underscores the urgent need for companies to adopt innovative technologies that enhance production agility and responsiveness to market demands. As these robotics developments continue to unfold, the German manufacturing industry's landscape will likely transform, leading to unprecedented levels of efficiency and competitiveness on the global stage.

Top 10 Germany Machine Innovations Transforming the Manufacturing Industry

| Innovation | Description | Impact on Manufacturing | Year Introduced |

|---|---|---|---|

| Collaborative Robots | Robots designed to work alongside humans, enhancing efficiency. | Increased productivity and reduced worker fatigue. | 2015 |

| 3D Printing | Additive manufacturing for rapid prototyping and production. | Reduced lead times and material waste. | 2013 |

| AI-driven Analytics | Utilizing AI to analyze production data for optimization. | Enhanced decision-making and operational efficiency. | 2020 |

| Digital Twins | Real-time digital replicas of physical systems for monitoring. | Improved maintenance and operational performance. | 2018 |

| IoT Integration | Connecting machinery via the Internet for data sharing. | Enhanced monitoring and predictive maintenance capabilities. | 2017 |

| Robotic Process Automation | Automating repetitive tasks using software robots. | Reduced errors and improved scalability. | 2019 |

| Smart Factories | Fully integrated factories using advanced automation. | Maximized efficiency and resource management. | 2022 |

| Augmented Reality (AR) | AR technology for training and maintenance assistance. | Improved training efficacy and reduced downtime. | 2021 |

| Additive Manufacturing for Metals | 3D printing technology specifically for metal components. | Ability to produce complex geometries. | 2019 |

| Blockchain for Supply Chain | Using blockchain technology for traceability in manufacturing. | Increased transparency and security in supply chains. | 2021 |

Additive Manufacturing: The Rise of 3D Printing in German Industries

The landscape of manufacturing in Germany is rapidly evolving, driven by the transformative power of additive manufacturing, particularly through advancements in 3D printing technologies. This innovation is reshaping traditional production processes, allowing for more flexible, efficient, and sustainable manufacturing practices. According to a recent report by the German VDMA (Mechanical Engineering Industry Association), the market for additive manufacturing is projected to grow by over 25% annually, reaching an estimated value of €2.4 billion by 2025. This growth is fueled by industries seeking to shorten production cycles and reduce waste, thereby enhancing profitability.

One of the most significant benefits of 3D printing in manufacturing is its capacity for customization. Companies can now produce complex parts tailored to specific client requirements without the need for extensive tooling, which drastically lowers production costs and time. Furthermore, the integration of 3D printing with advanced materials, such as metal and composites, broadens the application possibilities, making it an attractive option across various sectors including automotive, aerospace, and medical devices.

**Tip:** To stay competitive in an increasingly digital manufacturing environment, companies should invest in training their workforce in 3D printing technologies and foster a culture of innovation. Encouraging collaboration between design and manufacturing teams can also lead to more effective utilization of additive manufacturing capabilities. By embracing these changes, businesses can better align themselves with the trends set forth by advancements in 3D printing.

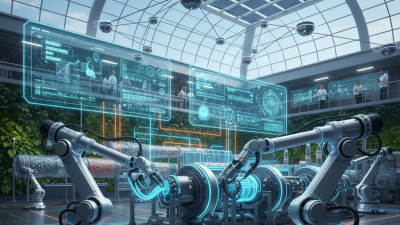

Smart Manufacturing: Integration of IoT in German Manufacturing Processes

The integration of the Internet of Things (IoT) in German manufacturing processes has marked a pivotal shift towards smart manufacturing. According to a report by the German Mechanical Engineering Industry Association (VDMA), approximately 70% of German manufacturers are expected to adopt IoT technologies by 2025. This shift is driven by the necessity to enhance operational efficiency and reduce production costs. IoT devices allow for real-time data collection and analysis, facilitating predictive maintenance and reducing machine downtime. With the capacity to gather and analyze vast amounts of data, German manufacturers are better equipped to adapt to changing market demands.

Moreover, IoT integration fosters collaboration across various segments of the manufacturing supply chain. A study by the Federal Ministry for Economic Affairs and Energy highlights that companies implementing IoT solutions have reported up to a 30% improvement in productivity. Enhanced connectivity not only streamlines internal processes but also improves communication with suppliers and partners, resulting in more agile and responsive manufacturing systems.

The utilization of IoT in German manufacturing represents a significant step toward achieving Industry 4.0, where automation and data exchange in manufacturing technologies lead to smarter and more efficient production lines, setting a benchmark for industrial innovation globally.

Sustainable Technologies: How Germany Is Leading Eco-Friendly Innovations

Germany has emerged as a leader in eco-friendly innovations in the manufacturing sector, embracing sustainable technologies that significantly reduce environmental impact. By harnessing advanced automation and smart technologies, German manufacturers are not only enhancing production efficiency but also prioritizing sustainability in their processes. This commitment includes the use of renewable energy sources, optimizing resource management, and minimizing waste through innovative techniques and materials.

Furthermore, Germany's focus on circular economy practices showcases its dedication to sustainability. Manufacturers are increasingly implementing strategies that promote the reuse and recycling of materials, thus reducing the demand for new resources. Innovations such as energy-efficient machinery and sustainable supply chain practices highlight how Germany is proactively addressing climate change challenges while maintaining its competitive edge in the global market. Through these initiatives, Germany is setting a precedent for the manufacturing industry worldwide, demonstrating that eco-friendly practices can go hand in hand with technological advancement.

AI and Data Analytics: Transforming Decision-Making in Manufacturing Operations

Artificial Intelligence (AI) and data analytics are revolutionizing the manufacturing industry by enhancing decision-making processes and streamlining operations. Through advanced algorithms and machine learning techniques, manufacturers can gather and analyze vast amounts of data in real-time. This capability enables them to identify patterns, predict equipment failures, and optimize production schedules, ultimately leading to increased efficiency and reduced operational costs.

The integration of AI tools allows for smarter resource allocation and minimizes downtime, as machines can alert operators to potential malfunctions before they impact production.

Moreover, data analytics empowers manufacturers to make informed decisions based on actionable insights derived from historical and real-time data. By leveraging predictive analytics, companies can forecast market demands more accurately, allowing them to adjust their production strategies accordingly. This not only helps in meeting customer requirements effectively but also supports inventory management and supply chain optimization.

The seamless integration of AI and data analytics into manufacturing operations signifies a shift toward a more agile and responsive industry, where businesses can adapt to changing market conditions swiftly while maintaining a competitive edge.

Related Posts

-

Top 10 Small Manufacturing Machines to Boost Your Business in 2025

-

Why Small Manufacturing Equipment is Essential for Your Business Growth

-

Top 10 Manufacturing Industrial Machinery Trends to Watch in 2023

-

How to Choose the Best Adult Diaper Machine for Your Needs

-

Why Simple Manufacturing Machines Are Essential for Modern Production

-

How to Choose the Right Manufacturing Equipment for Your Business Needs