How to Improve Efficiency in the Machine Industry?

In the rapidly evolving machine industry, efficiency is a critical factor. Companies often seek ways to optimize processes and reduce waste. Efficiency gains can lead to increased productivity and profit margins. However, achieving this is not simple. Many organizations face challenges in aligning new technologies with existing practices.

One common issue is resisting change. Employees may cling to outdated methods, hindering progress. Additionally, the integration of automation can create confusion. Not all teams adapt quickly. Machine maintenance practices can also limit efficacy, resulting in unexpected downtime. These factors often require introspection and adjustment.

Moreover, continuous training is necessary. Employees must stay updated on industry advancements. This fosters a culture of improvement. However, budget constraints often restrict such initiatives. Organizations should reflect on these challenges and seek creative solutions to enhance their efficiency in the machine industry.

Identifying Key Performance Indicators in Machine Industry Operations

In the machine industry, identifying key performance indicators (KPIs) is essential for efficiency. KPIs help organizations track progress and highlight areas needing improvement. Common KPIs include production speed, downtime, and defect rates. Focusing on these metrics allows teams to pinpoint inefficiencies in their operations.

Monitoring production speed can reveal bottlenecks in the workflow. If the speed lags, managers should investigate potential causes. Are machines operating at full capacity? Are workers properly trained? Small issues can lead to larger problems. Similarly, analyzing downtime is crucial. Understanding why machines halt can prevent future delays.

Quality control is another critical area. High defect rates often indicate underlying problems. Are materials subpar? Is there an issue with the machinery? Reflecting on these questions can guide teams toward actionable solutions. Setting up regular reviews of these KPIs fosters a culture of continuous improvement. It’s a cycle of learning and adaptation, which is vital for growth.

How to Improve Efficiency in the Machine Industry? - Identifying Key Performance Indicators in Machine Industry Operations

| Key Performance Indicator (KPI) | Description | Target Value | Current Value | Trend |

|---|---|---|---|---|

| Overall Equipment Efficiency (OEE) | Measures the percentage of manufacturing time that is truly productive. | 85% | 78% | ↓ |

| Machine Downtime | Total time machines are not operational. | < 5% | 10% | ↓ |

| Production Rate | Number of units produced in a given time frame. | 1000 units/hour | 950 units/hour | ↓ |

| First Pass Yield (FPY) | Percentage of products manufactured correctly without rework. | 90% | 85% | ↓ |

| Customer Satisfaction Rate | Measures how products meet customer expectations. | > 90% | 88% | ↓ |

Implementing Lean Manufacturing Principles for Enhanced Efficiency

Implementing lean manufacturing principles can dramatically enhance efficiency in the machine industry. Lean focuses on eliminating waste while improving processes. It requires cross-functional collaboration and a commitment to continuous improvement.

One effective tip is to map the value stream. This visual representation shows each step in the manufacturing process. Look for areas of waste, such as excessive movement or waiting times. This analysis can reveal hidden inefficiencies, leading to timely adjustments.

Another useful strategy is to cultivate a culture of continuous feedback. Encourage employees to share their thoughts on processes. Sometimes, the best ideas come from those on the shop floor. It’s important to create an environment where suggestions are welcome, even if they seem small. Small changes can lead to significant gains over time.

Reflections on challenges can also drive improvement. Not every lean initiative will succeed at first. Analyze what didn’t work and understand why. This allows for better strategies in the future. Embracing imperfection can lead to a more resilient operation.

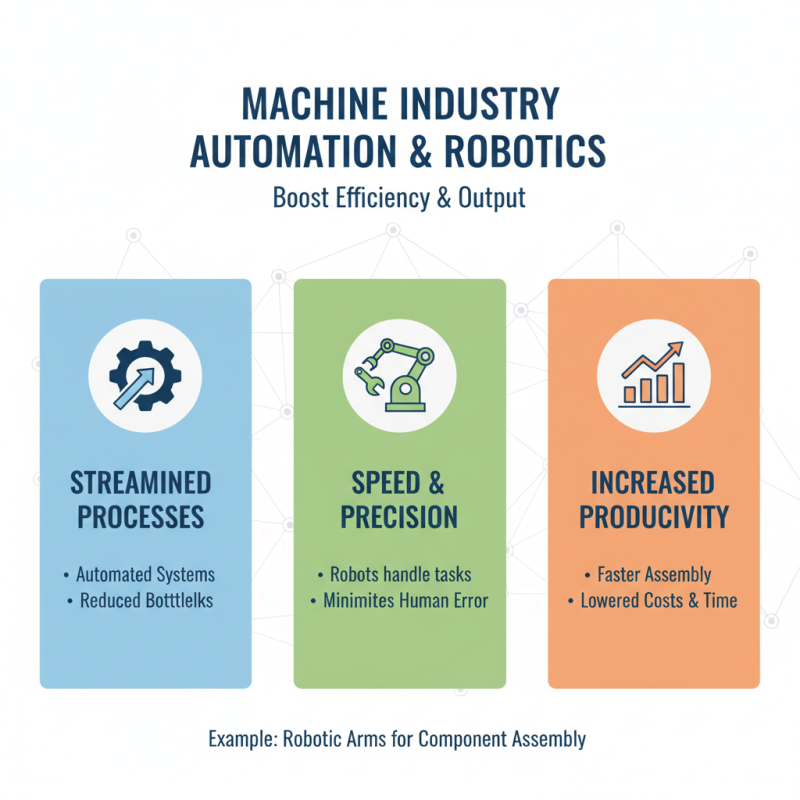

Leveraging Automation and Robotics to Streamline Production Processes

In today’s machine industry, automation and robotics offer significant potential to improve efficiency. By integrating automated systems, production processes can be streamlined. Robots can handle repetitive tasks with speed and precision. This reduces human error and increases output. For example, robotic arms can assemble components seamlessly. Many factories have notably lowered their production times and costs.

However, the transition to automation isn't without challenges. Workers may feel threatened by technology, leading to resistance. Training programs are essential to ease this shift. Employees need to develop new skills to work alongside machines. Moreover, these systems can require significant upfront investment. It’s important to weigh the long-term benefits against initial expenses.

Still, the impact of robotics can be transformative. A well-implemented system results in less downtime and higher quality products. Many industries have seen improvements in safety as well. Yet, companies must continually evaluate their processes. Not all automation is suitable for every situation. Regular reflection on methods is key to ensuring lasting success.

Enhancing Workforce Skills through Training and Development Programs

In the machine industry, enhancing workforce skills through training and development is crucial. Companies lose significant productivity due to skill gaps. A recent study showed that companies that invest in workforce training see a 25% increase in operational efficiency.

On-site training programs can focus on advanced manufacturing techniques. Interactive workshops help employees grasp new technologies better. Additionally, simulations offer a hands-on approach, fostering engagement. Yet, many companies overlook the need for ongoing education. Employees might feel stagnant without regular opportunities to upskill. A survey indicated that 50% of workers wish for more training options. Ignoring this demand can lead to higher turnover rates.

Development programs should also consider soft skills. Communication and teamwork are essential in many machine industry roles. However, these areas are often neglected. A diverse skill set promotes innovation and problem-solving. Companies should create tailored training experiences. This strategy can align workforce capabilities with business needs.

Adopting Advanced Technologies for Predictive Maintenance and Optimization

In the machine industry, adopting advanced technologies for predictive maintenance can significantly enhance efficiency. These technologies use data analytics and sensors to monitor machine health. By predicting failures before they happen, companies can reduce downtime. This leads to smoother operations and less waste.

Implementing predictive maintenance isn't without challenges. Training staff to use new technologies can be difficult. Additionally, integrating these systems into existing frameworks requires careful planning. Some facilities may resist change, fearing it might disrupt their routine. However, the potential benefits often outweigh these concerns. When properly executed, advanced maintenance strategies can lead to significant savings.

Optimization goes hand-in-hand with predictive maintenance. By analyzing data trends, companies can determine the best times for machinery servicing. This not only keeps machines running optimally but also ensures resources are utilized effectively. Yet, proper analysis requires skilled personnel, and finding these individuals is another hurdle. The road to efficiency is complex and requires continuous improvement and reflection.

Related Posts

-

How to Choose the Right Manufacturing Machine Parts for Optimal Efficiency

-

How to Choose the Right Manufacturing Equipment for Your Business Needs

-

What is Diaper Manufacturing Techniques and Their Importance in the Industry

-

Top 10 Manufacturing Machines Transforming the Industry in 2023

-

How to Choose the Best Adult Diaper Machine for Your Needs

-

2025 Top 5 Sanitary Pad Manufacturing Machines: Innovations Driving 10% Market Growth