Why Simple Manufacturing Machines Are Essential for Modern Production

In today's rapidly evolving industrial landscape, the significance of simple manufacturing machines cannot be overstated. Despite the increasing integration of advanced technologies such as robotics and automation, simple manufacturing machines continue to play a pivotal role in enhancing production efficiency. According to a report by the International Federation of Robotics, approximately 40% of new manufacturing processes still rely on traditional machinery due to their adaptability and cost-effectiveness. This reliance highlights the necessity of these machines in various sectors, from small-scale workshops to large manufacturing facilities.

The increasing demand for customized products requires a flexible approach to production, where simple manufacturing machines excel. With the global market for manufacturing technology expected to reach $10 trillion by 2025, simple machines offer manufacturers the ability to quickly adapt to changes in consumer preferences without substantial investment in complex systems. Moreover, they serve as essential training tools for new operators, reinforcing the foundational skills necessary for high-tech machinery operation. This adaptability and educational role illustrate why simple manufacturing machines are indispensable in modern production environments, ensuring both stability and growth in an increasingly competitive market.

The Role of Simple Manufacturing Machines in Production Efficiency

Simple manufacturing machines play a crucial role in enhancing production efficiency across various industries. These machines, characterized by their straightforward design and user-friendly operation, enable manufacturers to significantly reduce the time and labor involved in production processes. By automating basic tasks, they help streamline operations, allowing workers to focus on more complex and value-added activities. This shift not only maximizes the output but also reduces the likelihood of human error, ensuring consistent product quality.

Moreover, the affordability and ease of integration of simple manufacturing machines make them accessible to small and medium-sized enterprises (SMEs), contributing to a more competitive marketplace. These machines require minimal maintenance and training, facilitating quicker adoption and operational scaling. As production demands fluctuate, having simple yet effective machines allows manufacturers to adapt swiftly, ensuring they can meet customer needs without overextending their resources. The result is a more agile production environment where efficiency is not just a goal but a core component of everyday operations.

Types of Simple Manufacturing Machines Used in Various Industries

Simple manufacturing machines play a pivotal role in a wide range of industries, facilitating efficient production processes. These machines, such as lathes, drills, and milling machines, are often the backbone of workshops and factories. For instance, lathes are used extensively in metal and woodwork to shape materials with precision. They allow manufacturers to create complex designs while maintaining consistency and quality in parts production.

In addition to lathes, drilling machines are crucial in the construction and automotive industries, where they are used to create holes in various materials. These machines come in different configurations, including bench-top and portable models, making them versatile for various applications. Another essential machine is the milling machine, which removes material from a workpiece to produce flat surfaces, slots, and intricate designs. Its adaptability and precision make it invaluable for creating components that require tight tolerances. Overall, simple manufacturing machines are integral to modern production, enhancing efficiency and enabling innovation across diverse sectors.

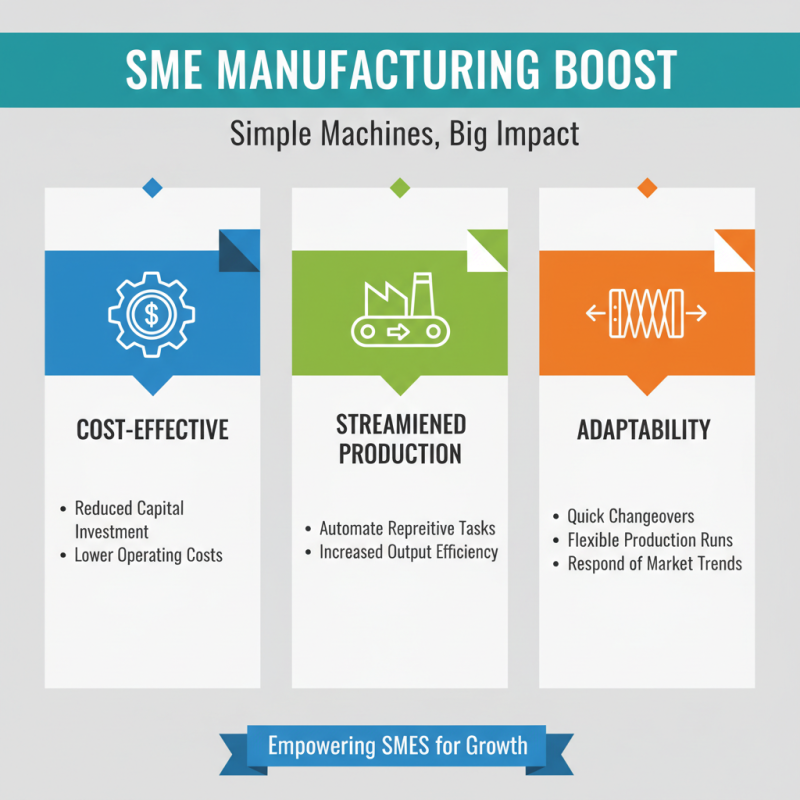

Benefits of Simple Manufacturing Machines for Small and Medium Enterprises

Simple manufacturing machines play a crucial role in enhancing the operational efficiency of small and medium enterprises (SMEs). These machines provide a cost-effective solution for businesses looking to streamline their production processes without the burden of significant capital investments. By utilizing straightforward designs and functionalities, these machines allow SMEs to maintain flexibility in their manufacturing practices, enabling quick changes to accommodate varying production demands. This adaptability is particularly valuable for smaller companies that may operate with limited resources and need to respond rapidly to market trends.

Moreover, simple manufacturing machines typically require less technical expertise for operation and maintenance, making them accessible for employees with diverse skill sets. This ease of use fosters a more inclusive workplace where employees can take on multiple roles, enhancing productivity. Additionally, these machines often have lower energy consumption and reduced maintenance costs, further enabling SMEs to optimize their overall operational expenses. As productivity and cost-efficiency become increasingly important in today's competitive landscape, simple manufacturing machines emerge as an essential asset for small and medium enterprises striving for sustainable growth.

How Simple Manufacturing Machines Facilitate Innovation and Customization

In today's fast-paced manufacturing environment, simple manufacturing machines play a pivotal role in driving innovation and customization. These machines, often easier to operate and maintain, provide manufacturers with the agility needed to respond rapidly to market demands. According to a report by the International Journal of Advanced Manufacturing Technology, companies that leverage simple machinery can pivot their production lines 30% faster than those reliant on complex systems. This flexibility is crucial for fostering creativity and enabling rapid prototyping, allowing teams to implement changes without incurring significant downtime or costs.

Moreover, the ease of customization offered by simple manufacturing machines is a game-changer for businesses looking to differentiate their products in a competitive marketplace. A survey conducted by McKinsey revealed that nearly 70% of consumers are willing to pay a premium for personalized products. By utilizing machines that facilitate quick adjustments and personalized features, manufacturers can cater to specific customer preferences, increasing customer satisfaction and loyalty.

Tips:

1. Embrace modular designs in simple manufacturing machines to enhance customization capabilities and streamline production adjustments.

2. Invest in training for operators to ensure they can efficiently use these machines, maximizing both innovation potential and operational efficiency.

3. Regularly assess and update your manufacturing processes to incorporate the latest advancements in simple machinery technologies, ensuring your operations remain competitive and responsive to new trends.

Challenges and Solutions in Integrating Simple Manufacturing Machines

The integration of simple manufacturing machines into modern production processes poses several challenges that businesses must navigate to capitalize on their benefits. One of the primary concerns is the compatibility of these machines with existing technologies. Many manufacturers rely on advanced, automated systems, making it difficult to incorporate simpler machines without effective interfacing solutions. This calls for a careful assessment of plant infrastructure and potentially upgrading certain components to ensure seamless operation, which can incur additional costs and downtime during the transition.

Another challenge is the workforce's adaptation to simpler machinery in an environment increasingly dominated by automation. Workers may require retraining to utilize these machines effectively, which can be a significant hurdle for businesses already facing labor shortages. Addressing this requires a strategic approach to training programs that emphasize both the operational skills needed for simpler machines and the benefits they bring, such as increased flexibility and lower production costs. By fostering an environment of continuous learning and adaptability, companies can not only ease the transition but also empower their workforce to leverage these machines effectively in their production systems.

Why Simple Manufacturing Machines Are Essential for Modern Production - Challenges and Solutions in Integrating Simple Manufacturing Machines

| Challenge | Description | Solution | Expected Outcome |

|---|---|---|---|

| Integration with Advanced Technology | Difficulty in combining simple machines with automated systems. | Implement modular control systems to facilitate communication between simple and advanced machines. | Improved efficiency in operation and reduced downtimes. |

| Skill Gap | Workforce may lack required skills to operate simple machinery optimally. | Provide training programs focused on basic manufacturing principles. | Increased worker productivity and reduced errors in operations. |

| Maintenance Challenges | Frequent breakdowns and maintenance requirements for older machines. | Adopt a preventive maintenance schedule and regular audits. | Enhanced machine lifespan and lower operational costs. |

| Cost Constraints | Budget limitations can hinder investment in necessary machines. | Explore leasing options or phased equipment upgrades. | Smoother cash flow management while improving manufacturing capabilities. |

Related Posts

-

Top 10 Manufacturing Machines Transforming the Industry in 2023

-

Why All Manufacturing Machines Are Essential for Modern Production Efficiency

-

What is Diaper Manufacturing Techniques and Their Importance in the Industry

-

2025 Top 5 Sanitary Pad Manufacturing Machines: Innovations Driving 10% Market Growth

-

Why You Should Invest in a Diaper Machine for Your Business Today

-

How to Choose the Right Manufacturing Equipment for Your Business Needs