Essential Tips for Choosing the Right Machinery Machine?

Choosing the right machinery machine is crucial for any business. It impacts efficiency, productivity, and bottom line. The process can be overwhelming. Different industries have unique needs. Selecting equipment that doesn’t fit can lead to costly mistakes.

Consider the tasks you need to perform. What materials will you work with? Size and capacity matter. A machinery machine must meet your specific requirements. Sometimes, small details are overlooked. This can result in poor performance or frequent breakdowns.

Budget is another important factor. Many options exist at varying price points. Investing in quality machinery can save money in the long run. But be careful with low-cost machines; they may not last. Reflect on your choices. The right machine could enhance your operation significantly.

Understanding Your Project Requirements and Objective Machinery Needs

Choosing the right machinery requires a clear understanding of project needs. Begin by identifying specific tasks your machinery must accomplish. This includes the scale of work, the materials involved, and the desired outcomes. For example, a construction project may need heavy earth-moving equipment, while a small workshop may only require basic tools. Knowing these details helps in narrowing down choices.

Next, consider the operational aspects. Think about the machinery’s capacity and efficiency. Will it handle peak loads? What about maintenance needs? Sometimes, machines appear perfect on paper but have hidden issues. Think about the training your team may need. A complicated machine can slow down production if everyone is not adequately prepared. Reflecting on these factors can lead to better long-term decisions.

Don’t forget the environment. Assess how the machine will fit into your workspace. Will it require special modifications? What about power sources or space for operation? You may find that a machine fits your budget but isn’t practical for your site. Such oversights can lead to costly adjustments later. It’s essential to align machinery choices with real-world conditions, ensuring that your project runs smoothly from the beginning.

Essential Tips for Choosing the Right Machinery Machine

Evaluating Machinery Types: Key Specifications and Functionalities

When selecting machinery, it’s crucial to focus on its specifications and functionalities. Different machinery types serve distinct purposes. For instance, a cutting machine may excel in precision, while a lifting machine prioritizes strength. Evaluating the operational capacity is vital. Can it handle the required weight? Is the speed sufficient for your projects?

Additionally, consider the type of materials the machine will work with. Some machines perform better with specific substances. Understanding the machinery's features can prevent costly mistakes. For example, a poorly fit machine can lead to inefficient operations. Remember, the right machine doesn’t always mean the most expensive one.

Moreover, research is not always straightforward. Some details may seem promising at first glance but can later reveal weaknesses. Consult manuals and user reviews. Seek opinions from colleagues. Sometimes, their insights highlight problems you might overlook. Balancing expectations with realistic capabilities fosters a better decision-making process.

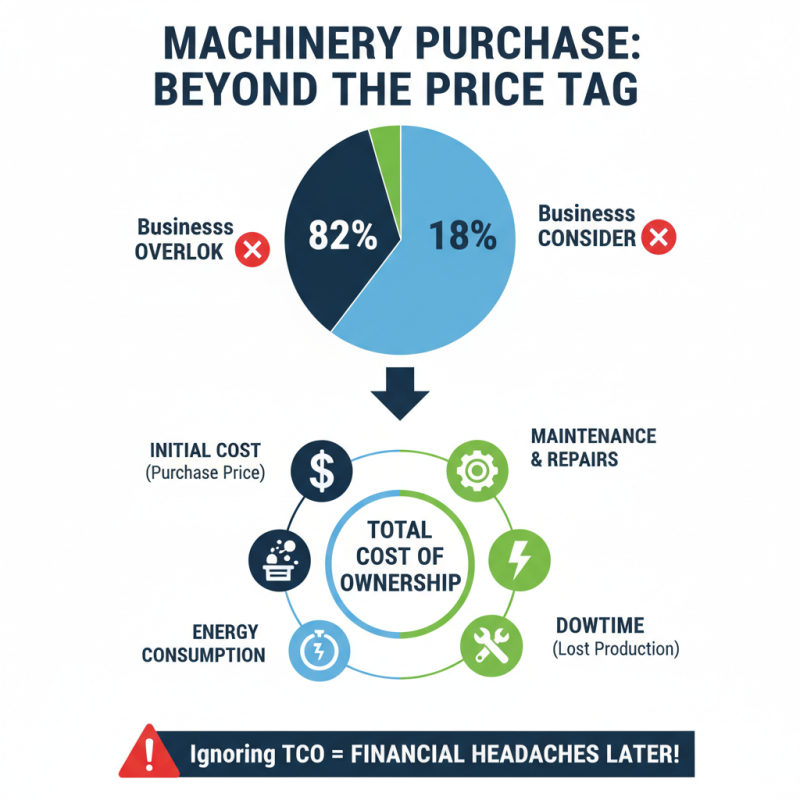

Budgeting for Machinery: Cost Analysis and Long-term Investment Value

When considering machinery purchases, cost analysis is crucial. A recent industry report suggests that 82% of businesses overlook total cost of ownership. This can lead to financial headaches later. Initial costs may seem low, but maintenance and operation expenses often skyrocket. Hidden costs can include energy consumption and downtime.

Long-term investment value should not be underestimated. Machinery that appears cheaper upfront might require more repairs over time. A well-maintained machine can offer up to 20% higher productivity. Investing wisely in machinery can pay off in the long run. Regular maintenance can decrease unexpected failures, which impact overall efficiency.

Analyzing budget constraints is essential. While it’s tempting to choose the lowest bid, consider quality. A report indicated that companies investing in high-quality machinery save 15% on operational costs annually. Comprehensive cost assessments can highlight potential savings. Balancing current budget and future needs is key. Aim for machinery that supports growth over time.

Assessing Supplier Reputation: Industry Standards and Certifications

When selecting machinery, assessing supplier reputation is crucial. Industry standards and certifications help gauge reliability. Suppliers with credible certifications show commitment to quality. Look for certifications that align with industry norms. These indicators often reflect a company's dedication to safety and performance.

Reviews from previous clients offer insights too. Look beyond flashy ads. A supplier may seem impressive but lack positive feedback. Inconsistent quality or late deliveries reveal deeper issues. Ask for references and follow up. Contact previous clients to gauge their experiences. Ask about machine performance and after-sales support.

Remember that no supplier is flawless. Some may have minor complaints but still offer good products. The trick is to weigh the pros and cons critically. A minor issue may not always indicate poor quality. Keep an open mind during your assessment. Trust but verify.

Maintenance and Support Options: Ensuring Longevity of Your Machinery

Maintaining machinery is crucial for maximizing productivity. According to a study by the National Association of Manufacturing, unplanned downtime costs manufacturers approximately $50 billion annually. This underscores the importance of establishing a robust maintenance plan for your machinery. Regular inspections and timely repairs can minimize breakdowns and extend machine life.

Support options should not be overlooked. Many manufacturers offer training for your staff. Employees equipped with knowledge can identify issues early. A survey found that 70% of equipment failures could have been avoided with better operator training. Additionally, consider the availability of spare parts. A long lead time for parts can halt operations, leading to expensive downtime.

Engaging with service contracts can also enhance support. A recent report showed that companies with service contracts experienced half the failure rates compared to those without. However, it’s important to read the fine print. Not all contracts cover the same aspects, and hidden costs may arise. Investing time in understanding these details can yield significant returns in machinery performance.

Related Posts

-

2025 Top 10 Manufacturing Industrial Machinery Innovations You Need to Know

-

How to Choose the Right Manufacturing Equipment for Your Business Needs

-

Top 10 Manufacturing Machinery and Equipment for Increased Efficiency

-

Top 10 Tips for Optimizing Manufacturing Machines for Maximum Efficiency

-

Why Small Manufacturing Equipment is Essential for Your Business Growth

-

2026 How to Optimize Industrial Machinery Manufacturing for Efficiency