Top 10 Diaper Manufacturing Equipment You Need for a Successful Factory

In the rapidly growing market for diapers, the need for efficient and high-quality diaper manufacturing equipment has never been more critical. As consumer demand continues to rise, manufacturers must ensure they are equipped with the right tools and technology to produce diapers that meet both quality standards and cost-effectiveness. The right diaper manufacturing equipment can significantly impact production efficiency, waste reduction, and overall product quality, making it essential for any factory aiming for success in this competitive industry.

Selecting the appropriate machinery is not merely about increasing output; it also involves understanding the whole manufacturing process—from raw material handling to the final product's packaging. Each piece of diaper manufacturing equipment plays a specific role that contributes to the overall performance of the production line. In this guide, we will explore the top 10 essential pieces of equipment that every diaper factory should consider investing in to optimize their operations and remain competitive. By focusing on innovation and quality in their manufacturing processes, companies can not only meet customer expectations but also set themselves apart in the highly lucrative diaper market.

Essential Equipment for Diaper Production: An Overview

When setting up a diaper production facility, equipping it with the right machinery is crucial for ensuring efficiency and quality in manufacturing. The essential equipment can broadly be categorized into several key areas, each serving a distinct role in the production process. First, high-speed tissue machines are necessary for producing the soft, absorbent layers that are fundamental to a diaper's performance. Additionally, ergonomic and automated converting machines streamline the process of assembling various components, such as elastic bands and absorbent cores, ensuring consistency and reducing labor intensity.

Moreover, a reliable quality control system is imperative to monitor production standards and reduce waste. This includes inline inspection machines that can detect imperfections or inconsistencies in the final product. Alongside these, packaging machinery plays a vital role in preparing the finished diapers for transport and sale, ensuring they are securely packaged to maintain hygiene and integrity. Investing in these key pieces of equipment will not only enhance production capabilities but also support the overall success of a diaper manufacturing enterprise.

Top 10 Diaper Manufacturing Equipment

Key Features of Diaper Manufacturing Machines

When setting up a successful diaper manufacturing factory, selecting the right equipment is crucial. Modern diaper manufacturing machines are designed with several key features that streamline the production process and ensure high-quality output. One essential feature is automation, which reduces labor costs and minimizes human error.

Automated systems can handle various stages of production, from material feeding to packaging, allowing for higher efficiency and consistent product quality.

Another critical aspect is versatility. Diaper manufacturing machines should have the capability to produce different types and sizes of diapers, catering to various market demands. This adaptability not only maximizes the use of machinery but also positions the factory to respond quickly to changing consumer preferences. Advanced safety features, such as emergency stops and protective barriers, are also paramount to ensure a safe working environment for operators. Furthermore, the integration of technology for real-time monitoring and data analytics can enhance production efficiency by quickly addressing any potential issues, ensuring that the factory operates at optimal levels.

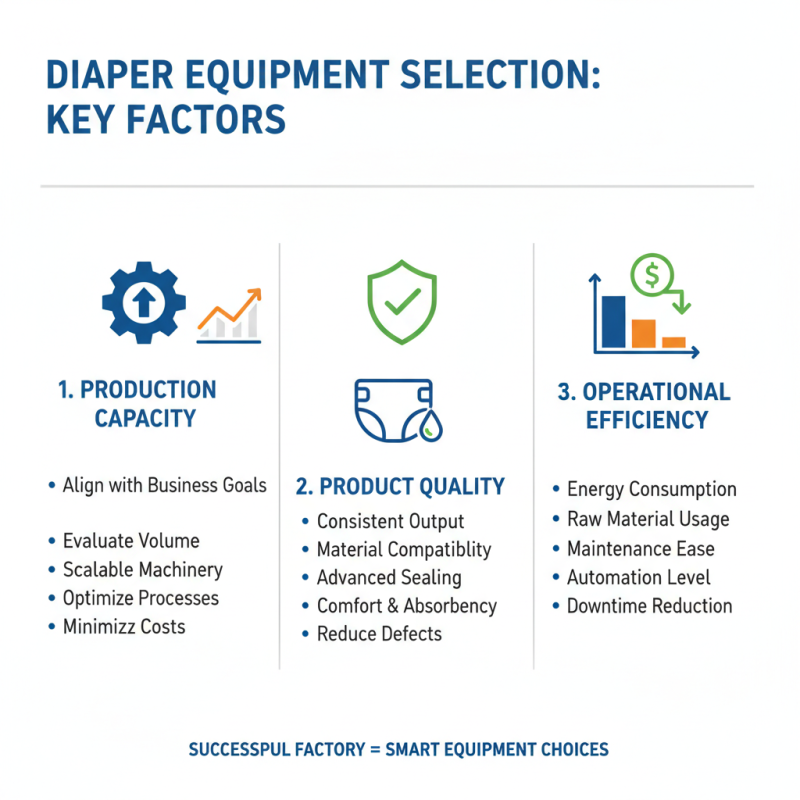

Factors to Consider When Choosing Equipment

When selecting diaper manufacturing equipment, several critical factors must be taken into account to ensure the success of your factory. First, the production capacity of the equipment should align with your business goals. Evaluate the volume of diapers you intend to produce, as this will dictate the size and efficiency of the machinery you need. Investing in equipment that can scale with your production demands will not only optimize manufacturing processes but also minimize costs in the long run.

Another essential factor to consider is the technology and automation level of the equipment. Modern diaper manufacturing requires sophisticated machinery that can handle various materials and production techniques efficiently. Look for equipment that incorporates automation to reduce manual labor, improve precision, and enhance overall production speed. Additionally, consider the ease of maintenance and availability of technical support for the machinery. Equipment that is user-friendly and easy to service can significantly reduce downtime, ensuring a smoother production flow and higher yield.

Maintenance and Optimization of Diaper Production Equipment

The success of a diaper manufacturing factory heavily relies on the maintenance and optimization of its production equipment. According to a report by Smithers Pira, the global market for disposable diapers is projected to reach approximately $75 billion by 2024, emphasizing the importance of efficient production processes. Regular maintenance of machinery can reduce unplanned downtime by up to 30%, significantly increasing overall productivity. By employing predictive maintenance strategies, factories can monitor the condition of their equipment in real-time, enabling timely interventions before breakdowns occur. This proactive approach not only minimizes costly停机 time but also extends the lifespan of the machines, providing a more sustainable operational model.

Additionally, optimizing the performance of diaper production equipment is critical for maintaining product quality and consistency. Data from a recent industry analysis suggest that implementing automation and advanced monitoring systems can increase production efficiency by an average of 25%. Automation reduces human error and enhances the precision of production processes. Furthermore, integrating data analytics into the workflow helps identify bottlenecks and areas for improvement. Regular training for maintenance staff and operators ensures they are equipped with the latest knowledge and skills, further bolstering the factory's operational capabilities and contributing to a more competitive edge in the diaper manufacturing market.

Top 10 Diaper Manufacturing Equipment You Need for a Successful Factory

| Equipment | Function | Maintenance Frequency | Optimization Techniques |

|---|---|---|---|

| Automated Cutting Machine | Cuts absorbent material to specified sizes | Daily | Regular calibration and blade sharpening |

| Forming Machine | Shapes and forms the diaper | Weekly | Lubrication and part alignment |

| Absorbent Core Assembly Machine | Assembles the absorbent layers | Monthly | Routine inspection for wear and tear |

| Wetness Indicator Applicator | Applies wetness indicators to diapers | Monthly | Check calibration and fluid levels |

| Diaper Folding Machine | Folds finished diapers for packaging | Weekly | Adjust folding angles and tension settings |

| Sealing Machine | Seals diapers for leakage prevention | Daily | Regularly check seal integrity |

| Packaging Machine | Packages finished diapers for shipping | Weekly | Monitor packaging speed and quality |

| Quality Control Station | Inspects diapers for defects | Ongoing | Implement feedback loops for improvements |

| Cleaning and Maintenance Equipment | Ensures hygiene and equipment upkeep | Daily | Use appropriate cleaning agents and check lists |

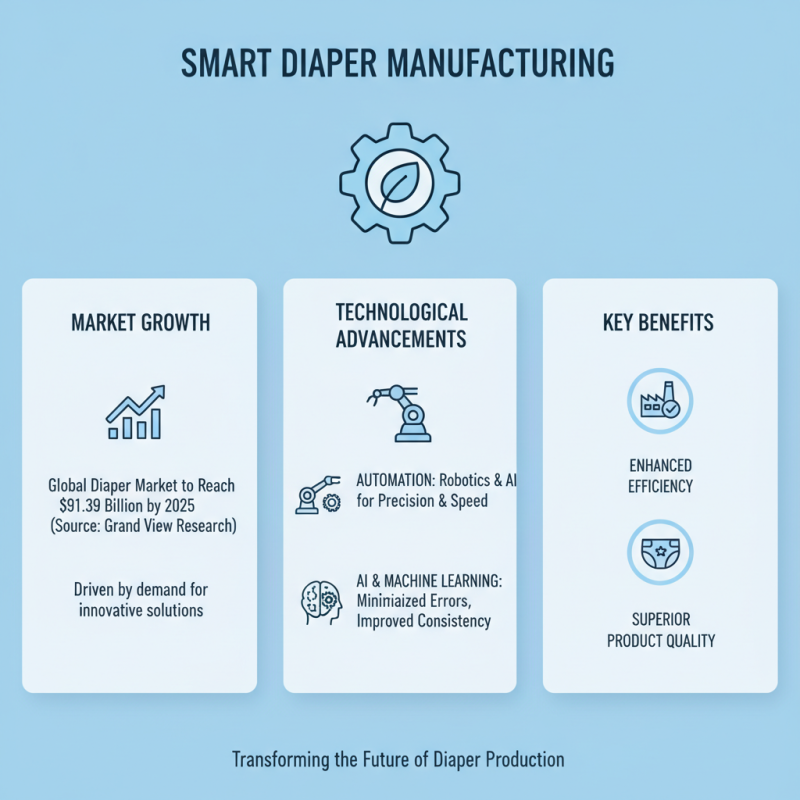

Emerging Technologies in Diaper Manufacturing Processes

The diaper manufacturing industry is witnessing a transformation driven by emerging technologies that enhance efficiency, reduce waste, and improve product quality. According to a recent market report by Grand View Research, the global diaper market is projected to reach $91.39 billion by 2025, highlighting the growing demand for innovative manufacturing solutions. Automation has become a cornerstone of modern diaper production, with advancements in robotics and Artificial Intelligence (AI) allowing for increased precision and speed in manufacturing processes. These technologies not only streamline operations but also minimize human error, leading to better consistency in product quality.

Furthermore, the integration of IoT (Internet of Things) in diaper manufacturing enables real-time monitoring of equipment and production lines, fostering predictive maintenance practices. A report from MarketsandMarkets indicates that the IoT in manufacturing market is expected to grow from $29.9 billion in 2020 to $52.5 billion by 2025, reflecting the rising importance of connected devices. This connectivity allows for data-driven decision-making, optimizing resource utilization and reducing operational costs. As manufacturers increasingly embrace these technologies, they will not only enhance productivity but also adapt more swiftly to consumer demands and market trends, underscoring the critical role of emerging technologies in the future of diaper manufacturing.

Related Posts

-

Why You Should Invest in a Diaper Machine for Your Business Today

-

Top 10 Diaper Manufacturing Equipment You Need for Efficient Production

-

How to Choose the Right Manufacturing Machine Parts for Optimal Efficiency

-

2025 Top 10 Manufacturing Industrial Machinery Innovations You Need to Know

-

What is Diaper Manufacturing Techniques and Their Importance in the Industry

-

Why All Manufacturing Machines Are Essential for Modern Production Efficiency