Top 10 Manufacturing Machinery and Equipment for Increased Efficiency

In the ever-evolving landscape of industrial production, the importance of advanced manufacturing machinery and equipment cannot be overstated. According to Dr. Emily Chen, a renowned expert in the field of manufacturing technology, "Investing in the right machinery is crucial for enhancing operational efficiency and meeting the demands of modern production." As industries strive to optimize their processes, identifying the top manufacturing machinery and equipment becomes paramount for maximizing productivity and minimizing downtime.

In recent years, technological advancements have significantly transformed manufacturing operations, driving the need for innovative machinery solutions that are not only efficient but also adaptable to changing market conditions. With automation and smart technologies on the rise, manufacturers are increasingly seeking equipment that integrates seamlessly into their manufacturing systems. By focusing on the latest trends in manufacturing machinery and equipment, businesses can position themselves for success in a highly competitive environment.

This article explores the top ten manufacturing machinery and equipment that are making waves in the industry, highlighting their impact on efficiency, output quality, and overall operational excellence. With the right tools at their disposal, manufacturers can enhance their workflows, reduce resource wastage, and ultimately achieve a new standard of excellence in production.

Overview of Manufacturing Machinery in Modern Industries

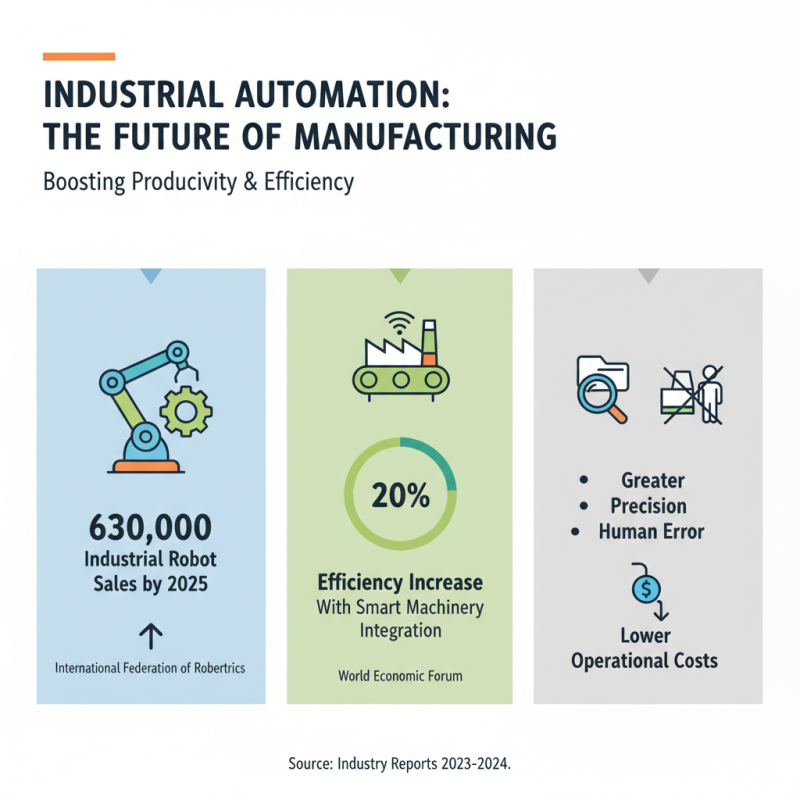

In modern industries, manufacturing machinery and equipment play a pivotal role in enhancing productivity and efficiency. According to a recent report from the International Federation of Robotics, by 2025, global industrial robot sales are expected to reach 630,000 units annually. This surge demonstrates the industry's shift toward automation, leading to greater precision and reduced human error. Furthermore, the World Economic Forum highlights that integrating smart machinery in production lines can improve efficiency by up to 20%, significantly lowering operational costs.

To maximize the potential of manufacturing equipment, companies should consider investing in advanced technologies like predictive maintenance systems. These technologies utilize data analytics to predict equipment failures before they occur, reducing downtime and associated costs. Additionally, implementing energy-efficient machinery can lead to substantial cost savings, with reports estimating that industries could save up to 30% on energy expenses by utilizing modern, energy-efficient equipment.

Tip: Regularly assess the machinery used in production processes to identify areas for improvement. Upgrading older equipment not only boosts efficiency but can also lead to enhanced product quality and employee satisfaction. Ensure that workforce training is aligned with technological advancements to fully leverage the benefits of new machinery and systems.

Key Factors Driving Efficiency in Manufacturing Equipment

The efficiency of manufacturing equipment is influenced by several key factors that play a crucial role in enhancing productivity and reducing operational costs. First and foremost, technology integration stands out as a primary driver. Advanced technologies, such as IoT devices and automation systems, allow for real-time monitoring and data analytics, enabling manufacturers to optimize processes, minimize downtime, and predict maintenance needs before they become critical. By streamlining operations, companies can significantly increase their overall efficiency.

Another vital factor is the design and adaptability of manufacturing machinery. Equipment that is modular and flexible can be quickly reconfigured to meet changing production needs without extensive downtime. This adaptability not only minimizes disruption but also supports a diverse range of manufacturing processes. Furthermore, energy efficiency should not be overlooked; machines that consume less energy can lower utility costs while contributing to sustainability goals.

By focusing on these key factors, manufacturers can enhance operational efficiency, leading to improved output and a stronger competitive edge in the market.

Top 10 Essential Machinery for Enhanced Production Capability

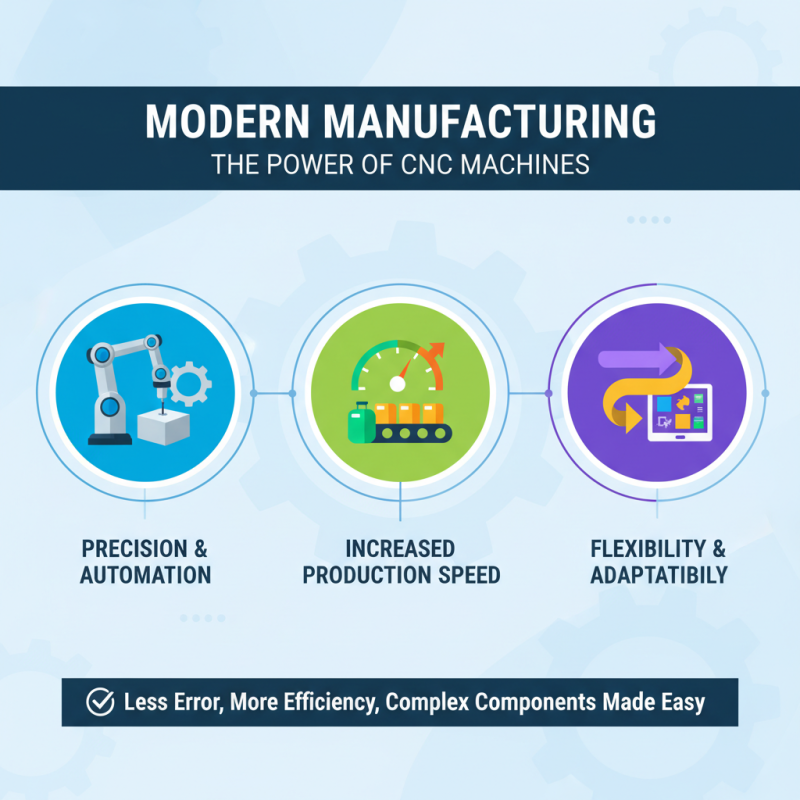

In modern manufacturing, the right machinery plays a pivotal role in enhancing production capability. One essential piece of equipment is the CNC machine, which automates precision machining processes. By significantly reducing human error and increasing production speed, CNC machines enable manufacturers to produce complex components with greater efficiency. Furthermore, they facilitate easy modifications in designs, offering flexibility in production runs that can adapt to changing market demands.

Another critical tool is the automated guided vehicle (AGV), which streamlines material handling processes. AGVs reduce the time spent in transporting goods between different areas of the manufacturing floor, thereby minimizing downtime and optimizing workflow. Additionally, the integration of robotics in assembly lines has revolutionized the production process. Robots not only increase speed and accuracy but also work tirelessly without fatigue, leading to an overall increase in throughput.

Investing in high-quality packaging machinery is also vital for enhancing production capabilities. Efficient packaging systems ensure that products are securely packed and ready for distribution in less time, thus improving supply chain efficiency. Overall, the strategic incorporation of these essential machinery types can lead to remarkable improvements in productivity and operational success in manufacturing enterprises.

Innovative Technologies Transforming Manufacturing Equipment

Innovative technologies are revolutionizing the manufacturing sector, enhancing efficiency and productivity like never before. One significant advancement is the integration of the Internet of Things (IoT) in manufacturing machinery. This technology enables real-time data collection and analysis, allowing manufacturers to monitor equipment performance and operational workflows. As a result, companies can identify bottlenecks and inefficiencies, adjust processes proactively, and reduce downtime, all of which contribute to a more streamlined production environment.

Another transformative development is the rise of automation and robotics in manufacturing. Sophisticated AI-driven robots can perform repetitive tasks with precision and speed, minimizing human error and increasing output. Coupled with advanced machine learning algorithms, these systems can adapt to changes in production requirements, learn from previous tasks, and optimize operations continuously. This shift not only enhances production capacity but also allows human workers to focus on more complex and creative tasks, thereby fostering innovation within the workforce.

Best Practices for Implementing Efficiency-Boosting Machinery

Implementing efficiency-boosting machinery in manufacturing requires a strategic approach that considers both technology and the workforce. First, it is essential to conduct a thorough needs analysis to identify specific bottlenecks in the production process. By understanding where delays and inefficiencies occur, manufacturers can select machinery that directly addresses these issues. For instance, automating repetitive tasks can free up human resources for more complex operations, thus optimizing overall productivity.

Furthermore, maintaining a balance between technology integration and employee training is crucial. Equipping staff with the necessary skills to operate and troubleshoot new machinery ensures that any potential downtime due to technical issues is minimized. Regular training sessions and workshops can foster a culture of continuous improvement, where employees feel empowered to suggest enhancements. Collaboration between machine operators and engineers can lead to innovative solutions that further enhance operational efficiency, creating a more agile manufacturing environment.

Top 10 Manufacturing Machinery and Equipment for Increased Efficiency

This bar chart showcases the efficiency improvements achieved through the implementation of various manufacturing machinery and equipment. Each type of machinery is represented along with its estimated efficiency percentage gain.

Related Posts

-

How to Choose the Right Manufacturing Equipment for Your Business Needs

-

Top 10 Manufacturing Machines Transforming the Industry in 2023

-

Top 10 Small Manufacturing Machines to Boost Your Business in 2025

-

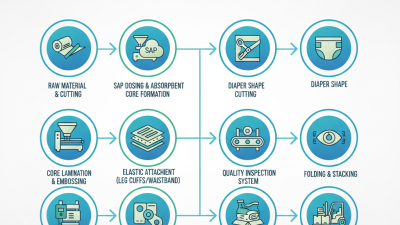

Top 10 Diaper Manufacturing Equipment You Need for a Successful Factory

-

Why All Manufacturing Machines Are Essential for Modern Production Efficiency

-

How to Choose the Right Manufacturing Machine Parts for Optimal Efficiency