Top 10 Manufacturing Machines Transforming the Industry in 2023

In the rapidly evolving landscape of modern industry, the significance of cutting-edge manufacturing machines cannot be overstated. As we step into 2023, manufacturers are increasingly turning to advanced machinery designed to enhance efficiency, reduce costs, and improve product quality. The integration of innovative technologies such as automation, artificial intelligence, and smart manufacturing systems have become critical to maintaining competitive advantages in an ever-changing market.

This year, manufacturers are leveraging a variety of transformative machines that not only streamline production processes but also pave the way for sustainable practices. The top manufacturing machines of 2023 are characterized by their ability to adapt to new roles within the production line, thereby optimizing operations and fostering collaboration between human workers and machines. Such advancements are redefining manufacturing processes, making them more agile and responsive to consumer demands.

As we explore the top ten manufacturing machines transforming the industry in 2023, it becomes clear that these tools are not just enhancing productivity but also driving innovation across various sectors. Understanding these revolutionary machines presents an invaluable opportunity for manufacturers to harness their potential, ultimately leading to a more efficient and prosperous manufacturing future.

Overview of Manufacturing Machines in 2023

The manufacturing landscape in 2023 is undergoing a significant transformation, driven by advancements in technology and the quest for efficiency. Automated machines are at the forefront of this revolution, with artificial intelligence and machine learning enabling smarter operations. This integration allows for real-time data analysis, predictive maintenance, and enhanced decision-making processes that minimize downtime and reduce operational costs. As a result, factories are becoming more agile and responsive to market demands.

In addition to automation, additive manufacturing continues to disrupt traditional processes. 3D printing technologies are enabling the production of highly complex components that were previously unfeasible or prohibitively expensive. This shift not only accelerates prototyping and reduces waste but also empowers manufacturers to create customized solutions tailored to specific customer needs. As sustainability becomes a key focus, these machines also help industries transition towards greener practices by optimizing material usage and reducing their carbon footprint. The overall outlook for manufacturing machines in 2023 reflects a commitment to innovation and the continuous improvement of productivity across various sectors.

Key Trends Driving Manufacturing Technology Innovation

In 2023, the manufacturing industry is witnessing a profound transformation driven by key technological innovations. One of the most prominent trends is the integration of artificial intelligence (AI) and machine learning, enabling machines to learn from data and improve processes autonomously. This real-time data analysis not only enhances production efficiency but also significantly reduces errors, leading to higher quality outputs. The adoption of AI in predictive maintenance is another game-changer, allowing manufacturers to anticipate equipment failures and minimize downtime, thereby optimizing overall production capabilities.

Moreover, the rise of sustainable manufacturing practices is reshaping industry standards. As environmental concerns take center stage, manufacturers are investing in energy-efficient machinery and processes that reduce waste and resource consumption. The shift toward circular economy models encourages the recycling of materials and the design of products with their end-of-life in mind, further driving innovation. These trends not only benefit the planet but also cater to the growing consumer demand for sustainable products, ensuring that manufacturers remain competitive in a rapidly evolving marketplace. In combination, these technological advancements and sustainability efforts are setting a new benchmark for the future of manufacturing.

Top 10 Machines Revolutionizing Efficiency and Productivity

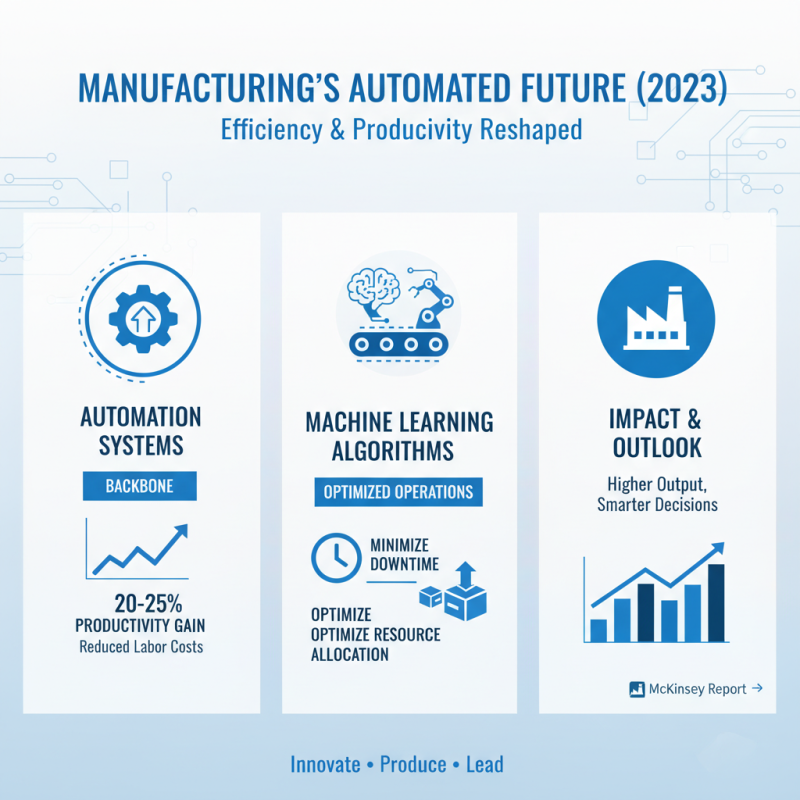

In 2023, the manufacturing landscape is being reshaped by advanced machines that prioritize efficiency and productivity. Among these transformative technologies, automation systems have emerged as the backbone of modern manufacturing. According to a report by McKinsey, the adoption of automation can lead to productivity gains of 20 to 25% in manufacturing processes, significantly reducing labor costs and increasing output. Machine learning algorithms integrated into production lines not only streamline operations but also enhance decision-making, allowing manufacturers to minimize downtime and optimize resource allocation.

Another significant advancement is the rise of additive manufacturing, commonly known as 3D printing. Research from Wohlers Associates indicates that the 3D printing market is projected to reach $32.78 billion by 2024, driven by its ability to produce complex parts at reduced lead times compared to traditional methods. This technology facilitates customization and flexibility in production, enabling manufacturers to respond more swiftly to market demands and reduce material waste. The implications are profound, as businesses can achieve higher production rates and improve overall operational efficiency without compromising on quality. As these machines continue to evolve, they are reshaping manufacturing paradigms, leading to unprecedented levels of efficiency and productivity in the industry.

Impact of Automation on Modern Manufacturing Processes

In 2023, the landscape of modern manufacturing has been dramatically reshaped by the relentless march of automation. The integration of advanced technologies such as artificial intelligence, robotics, and the Internet of Things (IoT) has revolutionized traditional manufacturing processes, enhancing efficiency and productivity. Automated systems are now capable of performing complex tasks with speed and precision, reducing human error and minimizing downtime. As a result, manufacturers are experiencing not just improved operational outcomes but also the ability to adapt swiftly to changing market demands.

The impact of automation extends beyond mere efficiency; it fosters innovation within the industry. By streamlining workflows, manufacturers can allocate resources to research and development, allowing for the creation of new products and improvement of existing ones. Moreover, smart manufacturing systems equipped with data analytics can offer valuable insights into production trends and consumer preferences, enabling companies to make informed decisions. As firms embrace automation, they position themselves to be more competitive in a rapidly evolving marketplace, ultimately leading to a more resilient manufacturing sector.

Future Outlook: The Evolution of Manufacturing Machines

The evolution of manufacturing machines in 2023 is marked by rapid advancements in technology and automation, significantly reshaping industrial processes. As per the latest industry reports, smart manufacturing, characterized by the integration of IoT (Internet of Things) and AI (Artificial Intelligence), is expected to increase production efficiency by up to 30% in the next few years. These intelligent systems can monitor machinery in real time, predict failures, and optimize production schedules, leading to significant cost savings and minimized downtime.

Furthermore, the adoption of additive manufacturing, or 3D printing, has been a game-changer in various sectors, allowing for the rapid prototyping of complex parts and reducing material waste. According to a recent study by market analysts, the global 3D printing market is projected to reach $44.2 billion by 2026, growing at a CAGR of 25.76%. This growth reflects the technology's ability to foster innovation in product design and customization, enabling manufacturers to respond more agilely to market demands while maintaining sustainability.

As we look ahead, the future of manufacturing machines will likely be defined by their adaptability and connectivity. With investments in advanced robotics and machine learning expected to exceed $30 billion annually, the industry is on the cusp of a transformation that promises not just increased productivity, but also a workforce that is empowered to work alongside these advanced systems, highlighting the importance of continuous skill development in this evolving landscape.

Related Posts

-

How to Choose the Right Manufacturing Equipment for Your Business Needs

-

How to Choose the Right Manufacturing Machine Parts for Optimal Efficiency

-

2025 Top 10 Manufacturing Industrial Machinery Innovations You Need to Know

-

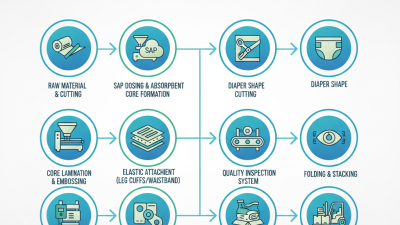

What is Diaper Manufacturing Techniques and Their Importance in the Industry

-

Why You Should Invest in a Diaper Machine for Your Business Today

-

Top 10 Diaper Manufacturing Equipment You Need for a Successful Factory