Top 10 Small Manufacturing Machines to Boost Your Business in 2025

In the rapidly evolving landscape of manufacturing, businesses are increasingly turning to small manufacturing machines to enhance efficiency, reduce costs, and optimize production processes. As we look to 2025, the rise of these compact yet powerful machines is transforming the way companies operate, allowing for greater flexibility and adaptability in a competitive market. These small manufacturing machines are not just a cost-effective solution for startups and small businesses; they also provide established manufacturers with the opportunity to upgrade their operations and stay ahead of industry trends.

The importance of incorporating small manufacturing machines into a production line cannot be overstated. With advancements in technology, these machines are becoming more sophisticated, offering features that enhance precision and scalability. Whether it's for 3D printing, CNC machining, or specialty assembly tasks, the versatility of small manufacturing machines enables businesses to cater to diverse customer needs and streamline workflow. As we delve into the top 10 small manufacturing machines for 2025, we will explore how these innovative tools can propel your business growth and position you for success in an increasingly automated world.

Top Manufacturing Trends Influencing Small Machine Selection in 2025

As we delve into 2025, several key trends are likely to significantly influence the selection of small manufacturing machines. One prominent trend is the increasing emphasis on automation and smart manufacturing technologies. Small manufacturers are seeking machinery that not only boosts production efficiency but also integrates seamlessly with IoT (Internet of Things) systems. This move towards automation helps in optimizing operations, reducing labor costs, and improving precision, making it paramount for businesses to choose machines that are compatible with advanced technologies.

Another important factor in machine selection is sustainability. As environmental concerns rise, small manufacturers are prioritizing energy-efficient machines that reduce waste and enhance resource utilization. Equipment that employs eco-friendly processes or materials is becoming crucial, allowing businesses to not only comply with regulations but also appeal to a growing market of environmentally conscious consumers. This shift towards sustainability not only benefits the planet but also drives cost savings in the long run, making it a vital consideration for production strategies in 2025.

Lastly, the demand for versatility cannot be overlooked. Small manufacturers are increasingly favoring machines capable of handling a range of tasks without the need for extensive reconfiguration. This flexibility allows businesses to respond swiftly to market changes and customer demands, enhancing their competitive edge. Machines that offer interchangeable modules or adaptable features will be at the forefront of small manufacturing operations, making them essential for success in the evolving landscape of 2025.

Essential Features of Small Manufacturing Machines for Modern Businesses

Small manufacturing machines have become critical assets for modern businesses, facilitating efficiency and enhanced production capabilities. When considering the essential features of these machines, versatility is paramount; businesses should invest in equipment that can handle a range of tasks, from simple assembly to complex fabrication processes. Reports from industry analysts suggest that flexible manufacturing systems are crucial for responding to market demands swiftly, with 78% of manufacturers acknowledging that adaptability is key for sustainable growth.

Another vital feature is technological integration. Many manufacturing firms are now leaning towards smart machines equipped with IoT capabilities. According to a recent survey by the Manufacturing Institute, 64% of manufacturers believe that adopting smart manufacturing technology can substantially lower operational costs. This includes features like real-time monitoring and predictive maintenance, which help minimize downtime and increase productivity.

Tips: When selecting a small manufacturing machine, always assess the scalability of the technology. Choose machines that can integrate with newer technologies as your business grows. Additionally, consider the energy efficiency of these machines; top-performing units can reduce energy costs by up to 30%, contributing to a more sustainable manufacturing operation.

Top 10 Small Manufacturing Machines to Boost Your Business in 2025

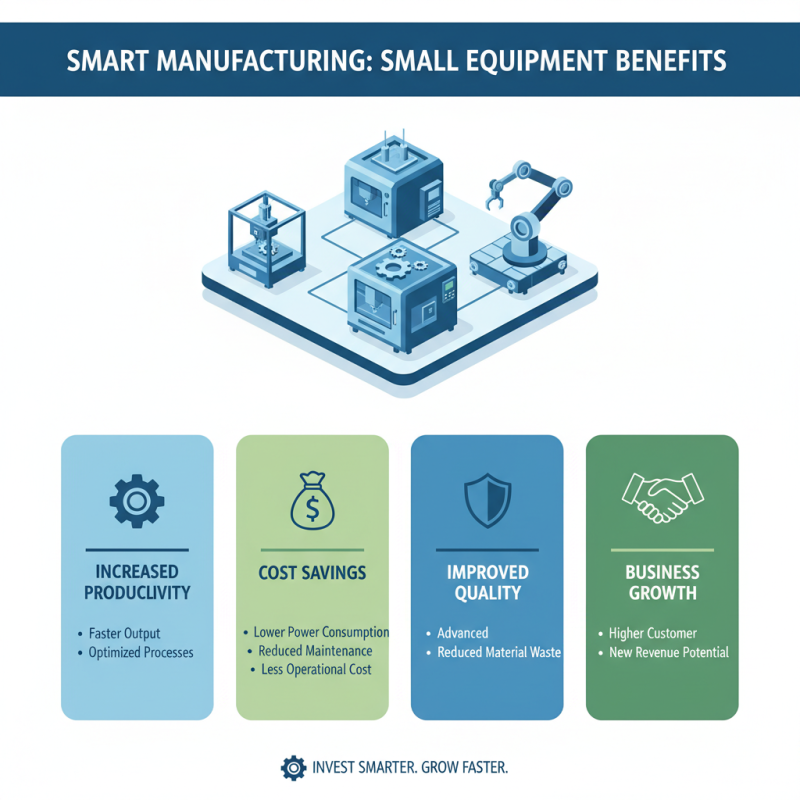

Cost-Benefit Analysis of Investing in Small Manufacturing Equipment

Investing in small manufacturing equipment offers significant benefits to businesses looking to enhance their productivity and efficiency. A cost-benefit analysis reveals that while the initial investment might seem substantial, the long-term savings and revenue potential often outweigh the costs. Small machines typically consume less power, require minimal maintenance, and have lower operational costs compared to larger counterparts, making them an attractive option for startups and small enterprises. Furthermore, these machines often come with advanced technology that can improve manufacturing processes, reduce waste, and enhance product quality, leading to increased customer satisfaction and repeat business.

Additionally, small manufacturing equipment can open up new market opportunities. By diversifying production capabilities, businesses can tailor their offerings to meet specific customer demands and trends. The flexibility that comes with smaller machinery allows companies to pivot quickly in response to market changes without the burden of hefty overhead costs associated with larger operations. This agility not only aids in maintaining competitive advantage but also positions businesses favorably for future growth, making the investment not just a financial decision, but a strategic one that can yield substantial returns over time.

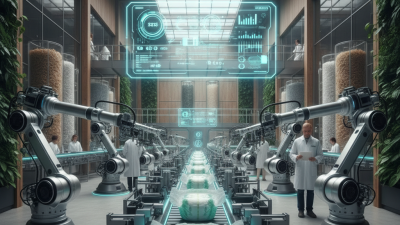

Emerging Technologies Enhancing Small Manufacturing Processes in 2025

As small manufacturing businesses strive to remain competitive in a rapidly evolving marketplace, emerging technologies in 2025 are playing a pivotal role in enhancing production processes. Automation, through the integration of advanced robotics and AI-driven systems, allows smaller manufacturers to optimize efficiency and reduce operational costs. These machines can perform repetitive tasks with precision and speed, enabling owners to allocate their workforce to more strategic roles that require human creativity and problem-solving skills.

Additionally, the rise of 3D printing technology is revolutionizing how small manufacturers approach product design and production. By enabling rapid prototyping and on-demand manufacturing, 3D printing reduces lead times and minimizes waste, allowing businesses to respond quickly to market demands. This adaptability not only enhances productivity but also encourages innovation by allowing small firms to experiment with new concepts without the significant upfront investment typically associated with traditional manufacturing methods. As these technologies continue to evolve, they present exciting opportunities for small businesses to enhance their capabilities and drive growth in 2025.

Top 10 Small Manufacturing Machines to Boost Your Business in 2025

| Machine Type | Primary Function | Key Features | Estimated Cost ($) | Expected ROI (%) |

|---|---|---|---|---|

| CNC Router | Wood and Metal Cutting | High Precision, Versatile | 25,000 | 150 |

| 3D Printer | Prototyping and Production | Fast Setup, Low Waste | 5,000 | 200 |

| Laser Cutter | Material Cutting and Engraving | Precision Cutting, Non-Contact | 35,000 | 100 |

| Desktop Injection Molder | Plastic Parts Production | Compact, User-Friendly | 15,000 | 120 |

| PCB Milling Machine | Circuit Board Production | Precision, Automated | 8,000 | 180 |

| Bench Press | Metal Forming | Heavy Duty, Reliable | 10,000 | 110 |

| Ultrasonic Cleaner | Part Cleaning | Thorough Cleaning, Safe | 1,500 | 250 |

| Portable Band Saw | Material Cutting | Lightweight, Easy to Maneuver | 2,500 | 160 |

| Heat Press Machine | Printing on Fabrics | User-Friendly, Fast Production | 3,500 | 140 |

| Digital Embroidery Machine | Textile Embroidery | High Speed, Multi-Needle | 6,000 | 175 |

Key Industry Data Supporting the Growth of Small Manufacturing Operations

The manufacturing landscape is undergoing a significant transformation, bolstered by advancements in technology and the increasing demand for customized products. According to industry research, small manufacturing operations are projected to grow at an unprecedented rate, driven by the rise of e-commerce and localized production. Key data indicates that the small manufacturing sector could expand by over 20% by 2025, highlighting the potential for entrepreneurs to tap into new markets with innovative solutions and efficient machinery.

Moreover, the push towards sustainability and eco-friendly practices is reshaping the small manufacturing industry. Reports suggest that consumers are increasingly prioritizing products made from sustainable materials, which encourages smaller manufacturers to adopt greener technologies. This shift not only helps manufacturers meet consumer demands but also opens up new avenues for funding and investment, as many organizations are keen to support businesses that align with sustainable goals. As small manufacturers embrace these trends and invest in the right machinery, they position themselves for long-term success and resilience in an ever-evolving market.

Related Posts

-

How to Choose the Right Manufacturing Machine Parts for Optimal Efficiency

-

What is Diaper Manufacturing Techniques and Their Importance in the Industry

-

Top 10 Diaper Manufacturing Equipment You Need for Efficient Production

-

2025 Top 10 Manufacturing Industrial Machinery Innovations You Need to Know

-

Why All Manufacturing Machines Are Essential for Modern Production Efficiency

-

How to Choose the Right Manufacturing Equipment for Your Business Needs