How to Use an Underpad Machine for Efficient Laundry Management?

In the world of laundry management, the use of an underpad machine is gaining traction. According to industry expert Dr. Sarah Thompson, "An underpad machine can drastically reduce cleaning time and improve efficiency." This tool is essential for both medical facilities and households that rely on absorbent underpads.

An underpad machine simplifies the cleaning process. It allows for fast drying and better sanitation. However, many users overlook the importance of proper maintenance. Regular check-ups on the machine can prevent unexpected breakdowns.

There are benefits, but also challenges. For example, the initial investment for an underpad machine can be high. Its operation requires some training. Individuals must know how to use it without damaging the fabric. Careful handling ensures that the lifespan of the machine is extended. Being mindful of these details can lead to a smoother laundry experience.

Understanding the Basics of Underpad Machines in Laundry Facilities

Underpad machines are essential in modern laundry facilities. They improve efficiency by automating the handling of absorbent materials. According to industry reports, these machines can increase productivity by up to 30%. This efficiency scales with the volume of laundry processed daily. Facilities handling large volumes can significantly benefit from their use.

Understanding how these machines function is crucial. They typically use heat and pressure to bond underpads, ensuring they hold up during usage. This bonding process can either save time or lead to unnecessary delays if not monitored. Data shows that improper adjustments can lead to a 15% reduction in overall performance. Regular maintenance and operator training can mitigate these issues.

Despite the advantages, challenges exist. Not every facility can afford the initial investment. The learning curve for new operators can be steep as well. Facilities must weigh the costs against potential gains. Efficiency depends on continuous improvement and reliable operation. Adapting to changes in demand remains a constant challenge.

Key Features and Specifications of Commercial Underpad Machines

When considering commercial underpad machines, it's essential to focus on their key features and specifications. These machines are designed to streamline laundry tasks involving absorbent underpads. Most models come with a high-capacity washer to handle large loads efficiently. A vital specification is their cycle speed. Many machines can complete a wash cycle in about 30 minutes, depending on the dirt level.

Another significant aspect is the heating system. High-quality machines use heated drying to ensure underpads come out dry and ready for use. Some models include adjustable settings. This feature allows users to cater the washing process to different fabric types. However, not incorporating the right product settings can lead to underperforming results. Users often overlook this.

Regular maintenance is also crucial for optimal performance. Cleaning the filters and checking the hoses can prevent clogs that slow down operations. Users sometimes forget this aspect, leading to unexpected breakdowns. Understanding the machine's features and specifications is worthwhile. This knowledge can enhance laundry management efficiency and improve operational workflows in any facility.

Optimal Workflow: Integrating Underpad Machines into Laundry Operations

Integrating underpad machines into laundry operations can significantly improve efficiency. According to research by the American Laundry Association, proper workflow management in laundry settings can boost productivity by 25%. An efficient layout is crucial. Positioning the underpad machine close to the drying area reduces handling time. Staff can quickly transfer wet items, minimizing wait times.

In many facilities, challenges arise during integration. Staff might resist change, leading to inconsistencies. Regular training is essential to address this. The National Institute for Occupational Safety and Health emphasizes that worker safety improves with better organized workflows. Ensuring machines are accessible and easy to operate is vital.

Maintenance also poses critical issues. Regular checks can prevent breakdowns. A study by the Textile Rental Services Association indicates that equipment downtime can cost operations up to $600 per hour. Scheduling maintenance during off-peak hours can limit disruptions. Finding the right balance between efficiency and employee comfort is key. Frequent feedback can help adapt processes for better outcomes.

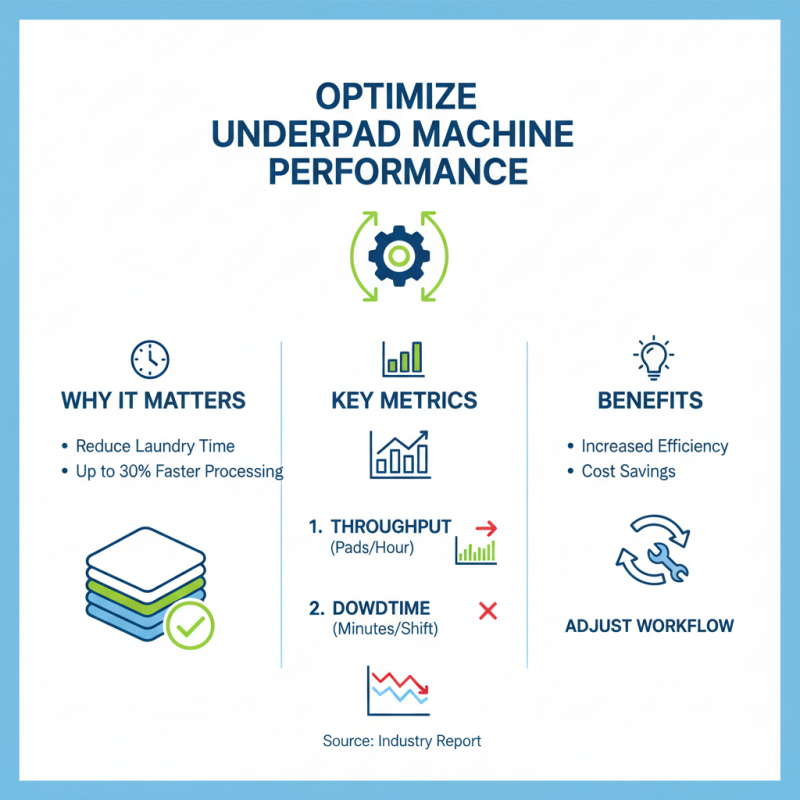

Underpad Machine Efficiency in Laundry Management

This chart illustrates the time efficiency at different stages of the laundry process when utilizing an underpad machine. As seen from the data, washing and drying stages consume the most time, highlighting potential areas for improvement through workflow optimization.

Efficiency Metrics: Measuring Underpad Machine Performance and Output

Measuring the performance of an underpad machine is crucial for efficiency. According to a recent industry report, optimal output can reduce laundry processing time by up to 30%. This is significant for facilities managing high volumes of linens. Evaluating key metrics like throughput and downtime can provide valuable insights. Monitoring these figures allows for adjustments in workflow.

Another report highlights that proper maintenance of underpad machines can cut failure rates by 25%. Regular checks and timely repairs prevent unexpected breakdowns. Unexpected downtime not only affects productivity but can lead to increased labor costs. Not every facility pays enough attention to these details.

In busy environments, it's essential to find a balance between speed and quality. Fast output may compromise cleanliness standards. A focus on these efficiency metrics helps identify areas for improvement. Facilities need to reflect on their current practices to achieve consistent performance. Continuous assessment of these metrics ensures long-term operational success.

Best Practices for Maintenance and Troubleshooting Underpad Machines

Maintaining an underpad machine can seem daunting. Regular maintenance ensures optimal performance and extends its lifespan. Check the machine daily. Look for any buildup or signs of wear. Clean the feeding trays after each use. Debris can impact efficiency and lead to breakdowns. Inspect the conveyor belts regularly. A worn belt can create uneven drying and affect the final product quality.

Troubleshooting is crucial for smooth operation. If the machine jams, don’t panic. Often, it’s a simple fix. Inspect the fabric feed for obstruction. Sometimes adjusting the tension resolves issues. Keep an eye on the moisture levels in your underpads. Too much or too little can lead to various problems. Document recurring issues. Over time, this can help identify patterns that need addressing.

Finally, remember to involve your team in maintenance practices. Share insights and discuss challenges regularly. Collective knowledge improves overall efficiency and morale. Sometimes, little mistakes occur, or instructions are ignored. Reflecting on these moments can pave the way for better routines. An engaged team leads to successful laundry management.

How to Use an Underpad Machine for Efficient Laundry Management? - Best Practices for Maintenance and Troubleshooting Underpad Machines

| Best Practices | Frequency | Tips |

|---|---|---|

| Pre-wash Inspection | Every Load | Check for wear and tear. |

| Proper Loading | Every Load | Avoid overloading for optimal performance. |

| Regular Cleaning | Weekly | Use mild detergents to maintain machine integrity. |

| Routine Maintenance Checks | Monthly | Inspect belts and electrical connections. |

| Troubleshooting Common Issues | As Needed | Refer to the user manual for error codes. |

| Temperature Settings | Every Load | Adjust based on fabric type. |

| Post-Wash Checks | After Every Load | Ensure all items are clean and in good shape. |

Related Posts

-

Top 10 Tips for Optimizing Manufacturing Machines for Maximum Efficiency

-

Top 10 Manufacturing Industrial Machinery Trends to Watch in 2023

-

Top 10 Diaper Manufacturing Equipment You Need for Efficient Production

-

What is Germany Machine and How Does It Impact Industry?

-

What is Diaper Manufacturing Techniques and Their Importance in the Industry

-

Why Simple Manufacturing Machines Are Essential for Modern Production